You can learn the recent information of Shijing.

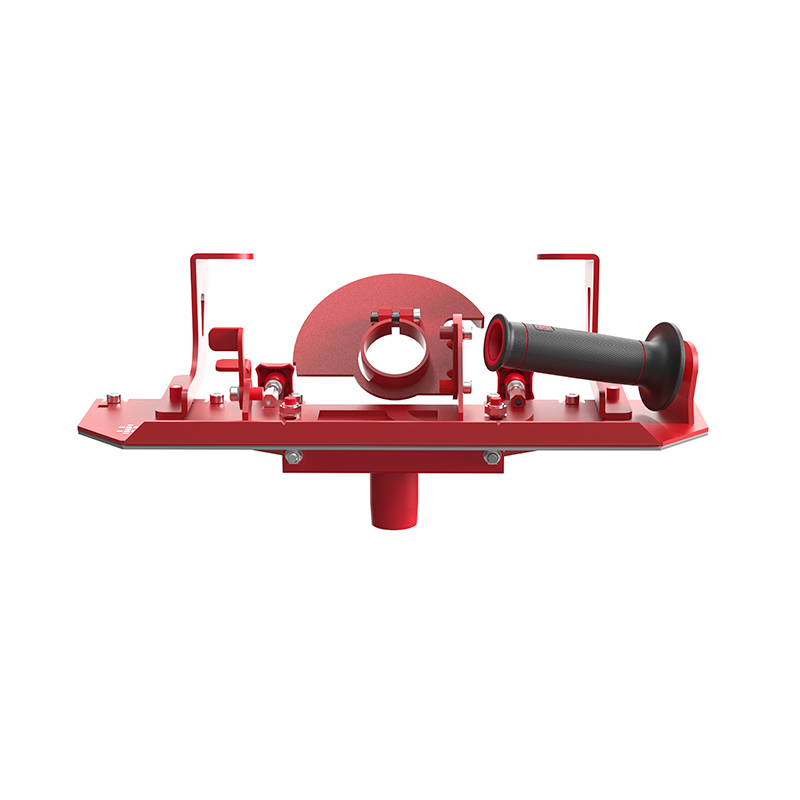

In the ever-evolving world of construction and home improvement, the Iron Base Plate Manual Tile Cutter has emerged as a cornerstone tool for professionals and DIY enthusiasts alike. Traditionally known for its reliability and precision, this essential tool is now undergoing a significant transformation, thanks to advancements in materials science. The integration of high-strength alloy iron into the construction of the Iron Base Plate Manual Tile Cutter is not just a minor upgrade; it represents a leap forward in durability, corrosion resistance, and overall longevity.

The Iron Base Plate Manual Tile Cutter has long been a staple in the tile installation industry. However, recent innovations in material science have led to the incorporation of high-strength alloy iron into its design. This material is not only stronger than conventional iron but also offers resistance to wear and tear. For instance, a manufacturer, TileMaster Tools, has reported that their latest Iron Base Plate Manual Tile Cutter models, which feature this new alloy, have demonstrated a 30% increase in durability compared to previous versions. This means that contractors and homeowners can expect their cutting tools to last longer, even under the demanding conditions.

One of the significant challenges faced by traditional Iron Base Plate Manual Tile Cutters is corrosion. Exposure to moisture and harsh chemicals during tile installation can to rust and degradation, compromising the tool's performance and lifespan. The introduction of high-strength alloy iron has effectively addressed this issue. This new material is highly resistant to corrosion, ensuring that the Iron Base Plate Manual Tile Cutter remains in condition for extended periods.

A case in point is a recent construction project in a coastal region, where high humidity levels posed a significant threat to tools. A contractor who had previously struggled with rusted tile cutters decided to switch to the new Iron Base Plate Manual Tile Cutter with alloy iron. After several months of continuous use in a highly corrosive environment, the tool showed no signs of rust or degradation. This real-world example highlights the practical benefits of the new material, which can save users both time and money by reducing the need for frequent replacements.

The use of high-strength alloy iron in the Iron Base Plate Manual Tile Cutter also contributes to improved precision and performance. The alloy's enhanced strength allows for a more stable and accurate cutting platform, ensuring that tiles are cut cleanly and accurately every time. This is particularly important in high-end construction projects where precision is paramount.

For example, a luxury hotel renovation project in New York City required the installation of thousands of custom-cut tiles. The project's contractor opted for the latest Iron Base Plate Manual Tile Cutter with alloy iron. The tool's stability and precision allowed the team to achieve a near-perfect installation, with minimal waste and rework. The project was completed ahead of schedule, and the end result was a stunning, seamless tile installation that met the standards of quality.

The market has responded positively to these innovations. Users of the new Iron Base Plate Manual Tile Cutter with alloy iron have reported significant improvements in their work processes. One professional tile installer, John Martinez, shared his experience: ""I've been using the Iron Base Plate Manual Tile Cutter for over a decade, and the new alloy iron version is a game changer. It's stronger, more durable, and the precision is unmatched. I've noticed a significant reduction in tile breakage and a smoother cutting process overall.""

Manufacturers are also seeing increased demand for these upgraded tools. TileMaster Tools, one of the pioneers in this material innovation, has reported a 40% increase in sales of their Iron Base Plate Manual Tile Cutter models featuring high-strength alloy iron. This surge in demand is a clear indication that the market is eager to adopt these new advancements.

As the construction and home improvement industries continue to evolve, the Iron Base Plate Manual Tile Cutter is poised to play an even more critical role. With ongoing research and development in materials science, we can expect further improvements in the durability, precision, and functionality of these tools. The integration of high-strength alloy iron is just the beginning. Future innovations may include smart features, such as integrated measurement systems and blade wear indicators, further enhancing the user experience.

The Iron Base Plate Manual Tile Cutter has come a long way from its humble beginnings. The introduction of high-strength alloy iron represents a significant milestone in its development. This new material not only enhances the tool's durability and corrosion resistance but also improves its precision and overall performance. Real-world examples, such as the coastal construction project and the luxury hotel renovation, demonstrate the practical benefits of these advancements. As the market continues to embrace these innovations, the Iron Base Plate Manual Tile Cutter is set to remain a vital tool in the tile installation industry, providing users with reliable, efficient, and precise cutting solutions for years to come

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

-2.jpg)

.jpg)

.jpg)

-1.jpg)

.jpg)

.jpg)