You can learn the recent information of Shijing.

-2.jpg)

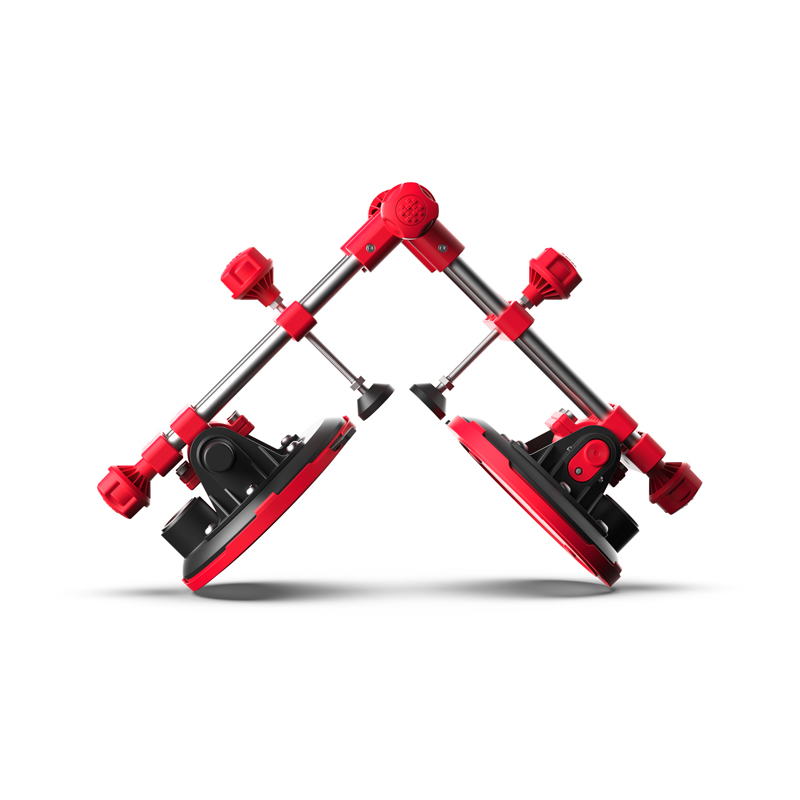

Vacuum suction cups have become an integral part of modern material handling, bridging the gap between manual labor and industrial automation. Their core principle is deceptively simple yet highly effective: by creating a vacuum between the cup and an object, atmospheric pressure firmly holds the object in place. This allows operators t o lift, move, or position heavy or delicate materials safely and efficiently, without causing surface damage or risking personal injury.

A vacuum suction cup typically consists of a flexible cup made from durable materials such as rubber, silicone, or synthetic polymers, combined with a mechanism to remove air and create a vacuum. Once the air is evacuated, the surrounding atmospheric pressure presses the object against the cup with remarkable force. This principle allows for the secure handling of objects ranging from glass panels to metal sheets, wood planks, and even delicate electronic components.

-2.jpg)

Modern vacuum suction cups have evolved far beyond the simple hand-held designs. Many now feature ergonomic handles, built-in manual or electric pumps, and lightweight portable constructions, making them ideal for both industrial and occasional use. Their applications span a wide range of industries, including construction, glass handling, warehousing, manufacturing, automotive, and electronics. The flexibility and efficiency offered by these devices make them indispensable tools in both manual and automated workflows.

Features and Materials of Vacuum Suction Cups

Vacuum suction cups are designed to be versatile, durable, and efficient. Their features include:

- Durable Materials: Commonly constructed from rubber, silicone, or specialized synthetic polymers, these cups resist wear, maintain flexibility, and provide reliable sealing over time.

- Surface Compatibility: Most suction cups are suitable for smooth, flat surfaces. Some specialized designs can handle slightly curved or uneven surfaces.

- Lightweight and Portable: Hand-held models are designed for easy operation, while larger industrial cups can be mounted on cranes or robotic arms for automation.

- Variety of Sizes and Capacities: Suction cups range from small models for delicate electronics to large versions capable of lifting hundreds of kilograms.

These features ensure that suction cups can handle a wide variety of materials, from fragile glass to heavy steel plates, while minimizing the risk of scratches, dents, or other surface damage.

How Are Industrial Suction Cups Used in Manufacturing?

Industrial suction cups are engineered for demanding environments, such as factories, warehouses, and assembly lines. They allow workers to lift, move, and position materials more safely and efficiently than manual handling methods. Typical applications include:

- Large Glass Panels: Used in construction, automotive, and electronics manufacturing.

- Metal Sheets and Plates: Facilitates movement in fabrication shops, automotive plants, and machine shops.

- Stone Slabs and Construction Materials: Enables safe handling of heavy slabs of marble, granite, or other construction materials.

The use of suction cups in industrial settings reduces the need for cranes, forklifts, or additional labor, while improving speed and precision in operations.

Types of Industrial Suction Cups

Industrial suction cups come in various designs to meet different requirements:

Flat Suction Cups

Flat suction cups are designed for smooth, completely flat surfaces, such as glass, polished metal, or finished stone. Their design maximizes contact area, ensuring strong holding power and stability during lifting and movement. Flat cups are widely used in glass manufacturing, sheet metal fabrication, and the automotive industries.

Bellows or Flexible Suction Cups

Bellows or flexible suction cups are engineered to adapt to slightly curved, uneven, or textured surfaces. Their accordion-like structure allows them to conform to the surface, maintaining a secure grip even on objects that cannot be handled with flat cups. These are particularly useful for handling irregularly shaped materials in construction and furniture manufacturing.

Multi-Cup Systems

For extremely heavy or oversized objects, multi-cup systems distribute weight across multiple suction points. These systems enhance safety by reducing stress on individual cups and ensuring stability during lifting. Multi-cup setups are common in glass curtain wall installation, large stone handling, and automotive assembly for large panels.

.jpg)

Benefits of Industrial Suction Cups

Industrial suction cups offer several advantages that make them a preferred choice in manufacturing and material handling:

- Safety: Reduces manual lifting risks, preventing worker injuries and surface damage.

- Efficiency: Speeds up material handling, assembly, and installation processes.

- Cost-Effectiveness: Eliminates the need for cranes or additional labor in many applications.

- Versatility: Can handle a wide range of materials, including glass, metal, wood, plastics, and composites.

The ability to lift and transport objects safely without permanent fixtures or complex machinery has made suction cups a staple in modern factories and warehouses.

Electric Suction Cups: Automated and Efficient

While manual and industrial suction cups remain popular, electric suction cups represent a significant advancement in automation and efficiency. Unlike manual suction cups that rely on human effort to create a vacuum, electric suction cups use motorized pumps to generate a vacuum automatically. This innovation allows for stronger, more consistent lifting and is particularly valuable in high-volume or repetitive operations.

What Makes Electric Suction Cups Different?

Electric suction cups offer several key advantages over traditional manual cups:

- Motorized Vacuum Creation: Automatic vacuum generation eliminates the need for manual pumping.

- Stronger Holding Power: Motorized systems provide higher vacuum levels, allowing for the lifting of heavier or more delicate items.

- Consistency: Electric cups maintain consistent vacuum levels over repeated cycles, improving reliability in assembly lines.

Integration with Automation: Can be mounted on robotic arms, conveyors, or automated gantries for fully automated material handling.

These features make electric suction cups an essential tool in modern automated factories, where speed, precision, and safety are paramount.

Applications of Electric Suction Cups

Electric suction cups are widely used in industries where repetitive lifting, precise placement, and surface protection are critical:

Automotive Industry

In automotive assembly, electric suction cups are used to lift and position windshields, car doors, hoods, and large body panels. Their precision and consistency reduce the risk of damage while increasing the speed of assembly operations. Robotic arms equipped with electric suction cups can handle panels weighing hundreds of kilograms with millimeter-level accuracy.

Electronics Manufacturing

The electronics industry demands care when handling delicate glass screens, circuit boards, and panels. Electric suction cups provide a gentle yet secure grip, allowing components to be lifted, placed, or assembled without risk of scratches or deformation. High-volume production of smartphones, tablets, and monitors heavily relies on this technology.

Robotics and Automation

Electric suction cups are increasingly integrated into robotic arms and automated production lines. In fully automated factories, they handle everything from packaging to assembly, eliminating repetitive manual tasks, enhancing efficiency, and ensuring consistent quality. Integration with sensors and feedback systems also allows electric suction cups to detect misalignment or insufficient vacuum, triggering automatic safety responses.

-1.jpg)

Advantages of Electric Suction Cups

Electric suction cups offer multiple operational advantages that make them good for industrial automation:

- High Lifting Capacity: Capable of handling extremely heavy objects safely.

- Time and Labor Savings: Automatic vacuum creation speeds up repetitive operations.

- Enhanced Safety: Built-in sensors and alarms prevent accidents caused by vacuum failure.

- Consistent Performance: Provides uniform lifting power across multiple cycles, crucial for high-volume production.

- Integration with Automation Systems: Easily incorporated into robotic and conveyor-based systems, enabling fully automated workflows.

Maintenance and Best Practices

To ensure longevity and reliability, vacuum and electric suction cups require proper maintenance. Key practices include:

- Regular Inspection: Check for cracks, wear, or deformation in the suction cup material.

- Cleaning: Remove dust, dirt, or debris from the cup surface to maintain a strong vacuum seal.

- Proper Storage: Store cups away from heat, sunlight, and chemicals that could degrade rubber or silicone.

- Vacuum System Maintenance: For electric cups, periodically check pumps, sensors, and valves to ensure consistent performance.

Following these good practices helps maintain efficiency, safety, and reliability in industrial operations.

Vacuum suction cups—whether manual, industrial, or electric—offer a safe, reliable, and versatile solution for lifting and moving heavy or delicate objects. By leveraging the simple principle of air pressure, they allow precise handling of materials such as glass, metal, wood, and plastics without causing surface damage.

Manual cups remain valuable for occasional or portable use, while industrial suction cups provide the strength and versatility required for demanding manufacturing environments. Electric suction cups, with their automated vacuum generation and integration into robotic systems, represent the cutting edge of modern automation. They enhance speed, consistency, and safety in high-volume production while reducing labor costs and operational risks.

Across industries such as construction, automotive, electronics, aerospace, and general manufacturing, vacuum suction cups have become indispensable tools. Choosing the right type of suction cup for a specific application, combined with proper maintenance and operational good practices, allows businesses to improve efficiency, reduce costs, and ensure workplace safety. In the era of automation and smart manufacturing, suction cups are not just tools—they are vital components that enable precision, safety, and innovation in material handling.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

.jpg)

.jpg)

-1.jpg)

.jpg)

.jpg)