You can learn the recent information of Shijing.

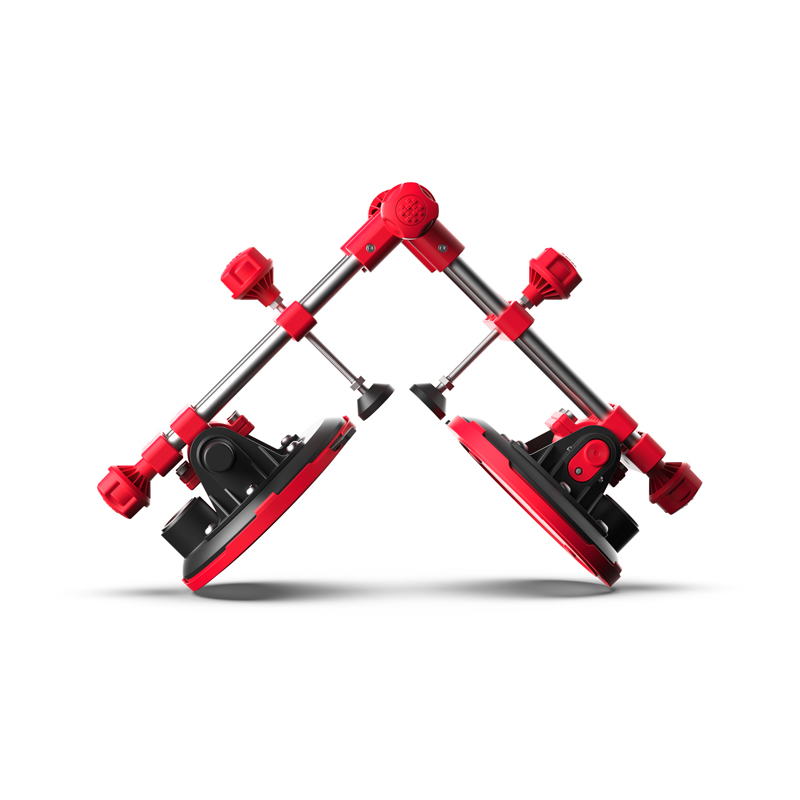

Achieving evenly placed tiles is a common challenge in construction and tiling projects. Uneven tiles or air pockets in mortar can cycle to shifting, cracking, or uneven surfaces. A Tile Vibrator addresses these issues by vibrating tiles during installation, helping to distribute mortar evenly and secure each tile in place. For businesses or contractors seeking regular equipment, sourcing directly from a Tile Vibrator Factory ensures consistent quality and performance across projects.

1. How Tile Vibrators Improve Accuracy

A tile vibrator works by transmitting vibrations to tiles, which helps settle them evenly into the mortar. This eliminates air pockets and reduces gaps under tiles that can cause future cracks or instability. Using a Tile Vibrator allows installers to maintain consistent alignment without relying solely on manual adjustments. Different vibration frequencies and amplitudes can be adjusted depending on tile size and surface requirements, providing precise control for various projects.

2. Electric vs. Manual Tile Vibrators

Tile vibrators are available in electric and manual versions. Electric models are more powerful and suitable for high-volume or large tile projects, providing steady and adjustable vibrations. Manual models, often hand-cranked, are ideal for areas without electricity or for smaller-scale projects. Both types are typically compact and lightweight, which makes them easy to maneuver in tight spaces or on vertical surfaces. A Tile Vibrator Factory often provides both options to cater to different installation needs.

3. Versatility Across Tile Types and Surfaces

Tile vibrators are effective on a range of tile materials, including ceramic, porcelain, and stone. Many models come with interchangeable tips or heads to match different tile sizes and shapes. This adaptability ensures that mortar is evenly distributed, whether installing floor tiles, wall tiles, or other types of surfaces. Using a versatile Tile Vibrator reduces the risk of uneven adhesion, supporting durable and long-lasting installations.

4. Ergonomics and Ease of Use

tile vibrators are designed with ergonomics in mind, featuring comfortable grips and lightweight construction to reduce operator fatigue. Proper usage involves placing the vibrator tip on or near the tile, activating vibrations, and monitoring the tile's movement until it is fully settled in the mortar. Even less experienced installers can use the tool effectively after brief guidance. Equipment sourced from a reliable Tile Vibrator Factory is often designed to strike a balance between performance and user comfort, which helps maintain productivity across extended work periods.

5. Choosing a Reliable Tile Vibrator Factory

Selecting a reputable Tile Vibrator Factory ensures consistent product quality and performance. Factories with industry experience produce vibrators from durable materials like steel or aluminum and conduct thorough testing for reliability. This reduces maintenance needs and ensures each unit delivers stable vibrations for consistent tile installations. Support services, including replacement parts and guidance on usage, also contribute to long-term performance. Investing in tools from a trusted factory helps construction teams maintain project schedules without interruptions caused by faulty or inconsistent equipment.

A Tile Vibrator is a practical tool that supports accurate, even, and long-lasting tile installations. Addressing common challenges such as air pockets, shifting tiles, and uneven mortar, it improves both quality and efficiency on-site. Sourcing from a trusted Tile Vibrator Factory guarantees equipment reliability, durability, and support for ongoing projects. Proper use and basic maintenance allow teams to achieve consistent results across a variety of tile types and installation settings, reducing the need for corrections and enhancing project outcomes.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

-2.jpg)

.jpg)

.jpg)

-1.jpg)

.jpg)

.jpg)

.jpg)

-3.jpg)