You can learn the recent information of Shijing.

.jpg)

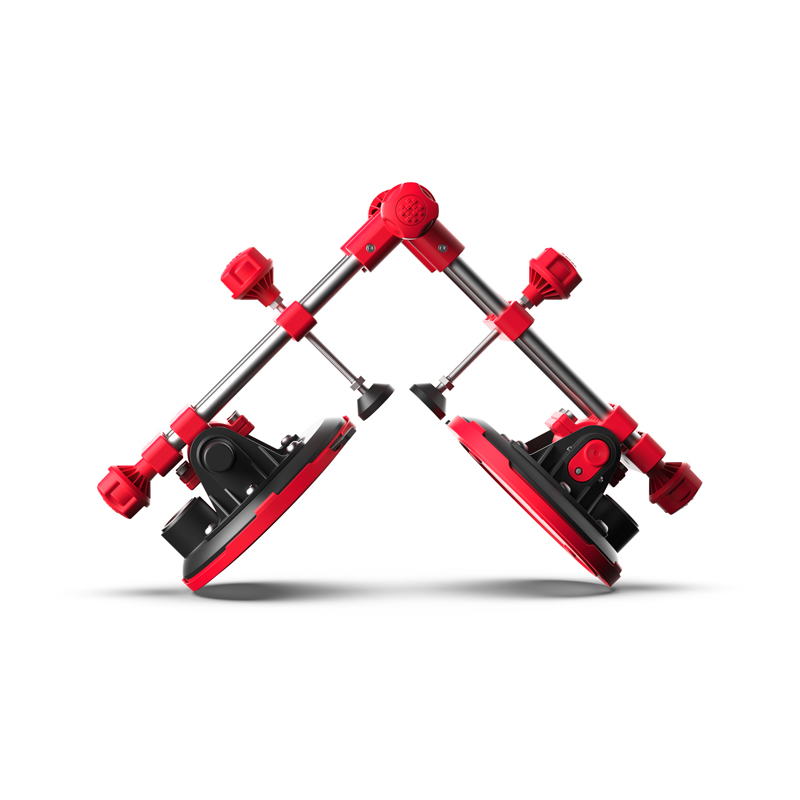

Accurate alignment remains a significant challenge in tiling and general construction work. Even small misalignments can cycle to uneven floors, crooked walls, or repeated adjustments, which increase labor costs and project time. A Laser Level simplifies this task by projecting a precise guideline or grid across a surface, allowing teams to install tiles or fixtures evenly. Using a laser tool reduces reliance on manual measurements and enhances overall consistency. For businesses that require regular equipment supply, sourcing directly from a Laser Level Factory guarantees quality and reliability, ensuring each tool meets project demands.

.jpg)

How a Laser Level Enhances Accuracy

Precision is one of the primary reasons construction professionals rely on a laser level. Unlike traditional methods such as spirit levels or chalk lines, a tile laser level projects a highly visible line that acts as a guide for installation. This ensures tiles, cabinets, or other components are aligned correctly from the start. A straight line or grid projected by a laser helps installers maintain the intended pattern without frequent corrections. Additionally, a Laser Level allows for adjustments at different angles, which is particularly useful when handling non-standard layouts or complex room geometries. By eliminating guesswork, it reduces the risk of costly mistakes and supports higher-quality outcomes.

Efficiency and Time Savings

One of the common pain points in construction is balancing quality with speed. Traditional measuring methods can be slow and prone to errors, especially on large projects. A laser level addresses this by allowing multiple reference points to be marked simultaneously. For example, when tiling a floor, the laser can project both horizontal and vertical lines to guide the entire layout. This accelerates the process, reducing time spent on repeated measurements or adjustments. The lightweight and portable design of laser levels also contributes to efficiency, allowing teams to move quickly between work areas. Projects that previously required several hours of preparation can now be completed with fewer interruptions, all while maintaining accuracy with a Laser Level.

.jpg)

Versatility Across Applications

A tile laser level is not limited to one type of surface. It is effective for floors, walls, and ceilings, making it a versatile tool for different construction tasks. Whether working with ceramic, porcelain, stone, or composite tiles, a laser level provides a consistent guide that can adapt to varied material types. Some models even allow the projection of multiple lines or grids simultaneously, which is helpful for complex patterns or large-scale installations. For contractors or factories that handle a variety of projects, selecting equipment from a reliable Laser Level Factory ensures that each device is tested for accuracy and durability. The adaptability of the laser level makes it a valuable tool for diverse construction applications.

Choosing a Reliable Laser Level Factory

The consistency of a laser level's performance depends heavily on its production quality. Selecting a Laser Level Factory with proven industry experience ensures that each tool meets rigorous accuracy and durability standards. Reliable factories use quality components and follow strict assembly processes, which minimize calibration drift and maintenance needs. This is particularly important for contractors or businesses that rely on repeated use, as inaccurate equipment can disrupt timelines and increase costs. In addition, many factories offer support services, including replacement parts and guidance on maintenance, helping teams maintain consistent performance throughout the lifespan of the tool. Choosing the right factory means access to devices that support both daily operations and long-term project planning.

A Laser Level is a practical solution for achieving accurate and consistent results in construction and tiling projects. It improves precision, saves time, and simplifies operations across floors, walls, and ceilings. By sourcing tools from a reputable Laser Level Factory, teams benefit from reliable equipment that maintains its accuracy over time. With proper usage and basic maintenance, laser levels offer lasting value, reducing errors and supporting efficient workflows.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

-1.jpg)

.jpg)

.jpg)

.jpg)

-5.jpg)