You can learn the recent information of Shijing.

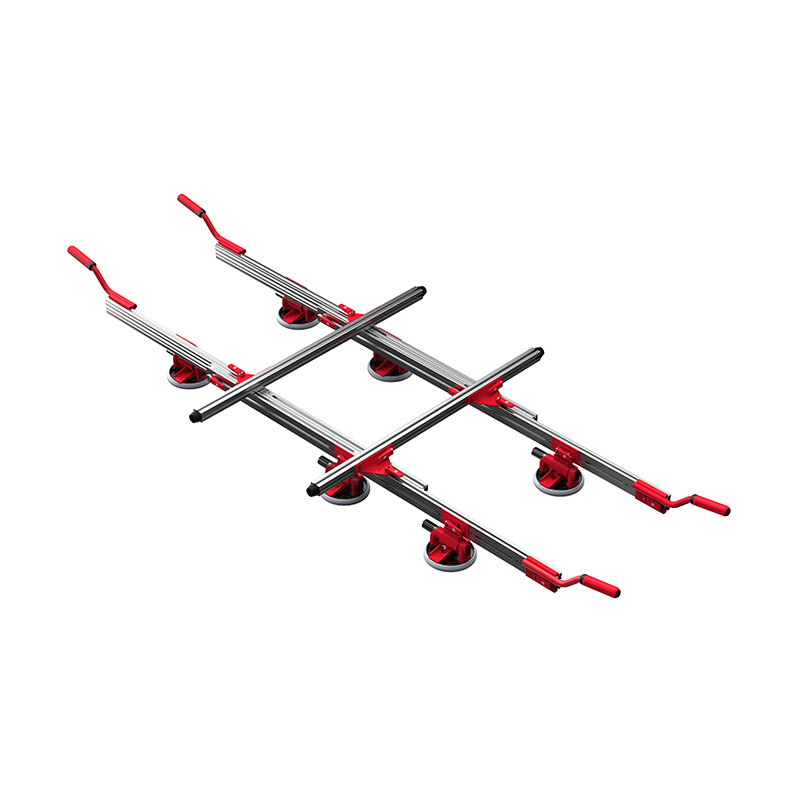

A Vacuum Suction Cup is a specialized lifting tool designed to handle heavy, flat, and smooth materials. It operates on the principle of creating a vacuum seal between the rubber pad and the object's surface, generating holding force without mechanical clamps. This feature makes it suitable for delicate surfaces, where direct gripping or clamping could cause damage. Common applications include glass panels, stone slabs, metal sheets, and other flat materials used in construction, manufacturing, and interior installation projects.

From a factory perspective, consistency and reliability are central. A professional Vacuum Suction Cup Factory ensures that each unit meets strict standards for pad flexibility, seal integrity, and handle strength. These considerations affect how the tool performs during repeated lifting tasks, providing stable performance on diverse surfaces.

Common Handling Challenges and Practical Solutions

Manual handling of heavy or delicate panels presents several challenges. Workers often face alignment issues, risk of surface scratches, and physical strain. Traditional methods, such as using clamps or straps, require multiple contact points and careful positioning, which can slow down operations. A Vacuum Suction Cup provides direct, centralized contact that spreads the lifting force evenly across the surface. This minimizes potential damage while simplifying the lifting process.

On busy job sites, repeated lifting is common. Using a Vacuum Suction Cup allows faster attachment and release compared with conventional methods. For example, during glass installation or stone wall placement, the tool allows technicians to lift, move, and align panels with less effort and time. Heavy-duty models extend this advantage to thicker, larger, and heavier materials, increasing operational efficiency.

Industries That Rely on Heavy-Duty Designs

Heavy-duty Vacuum Suction Cups are applied in multiple industrial sectors. In construction, they assist with glass walls, windows, and stone elements. Manufacturing environments use them to move metal plates, machine components, or assembly line materials safely. Automotive workshops depend on them for handling car windshields, body panels, and maintenance tasks.

In the marine and aerospace sectors, Vacuum Suction Cups help lift and align large components with smooth surfaces, supporting safe assembly and maintenance work. The entertainment industry also benefits, using these tools to move stage panels, props, and equipment during setup and teardown. An experienced Vacuum Suction Cup Factory customizes size, suction capacity, and handle design based on the intended use, ensuring suitability across applications.

Key Operating Factors That Affect Performance

Performance depends on both tool quality and surface conditions. Smooth, clean, and non-porous surfaces provide good vacuum formation. Even small particles of dust, dirt, or debris can reduce holding force. Many Vacuum Suction Cups include a pump or manual handle to remove air and create a stable vacuum, while some heavy-duty models integrate a mechanical release for controlled detachment.

Material selection is critical for durability. Rubber pads need to retain elasticity across repeated cycles, while handles and connectors must withstand lifting heavy loads without bending or breaking. A Vacuum Suction Cup Factory typically tests products under repeated use conditions to verify consistent suction and ergonomic handling. Clear instructions for inspection, attachment, and storage further support efficient use.

Manufacturing Perspective on Consistency and Reliability

From a production standpoint, consistency across units is essential. Standardized molds, regulated rubber mixing, and precise assembly processes ensure predictable performance. These measures reduce variability, which is critical when tools are used by multiple workers or across different sites.

A well-designed Vacuum Suction Cup integrates seamlessly into the workflow. It allows workers to lift, move, and place objects reliably while minimizing strain and handling time. Products from an experienced Vacuum Suction Cup Factory deliver consistent performance, maintain holding strength over time, and adapt to a variety of industrial environments. This reliability makes them an effective, versatile, and practical solution for companies that handle heavy flat materials regularly.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

.jpg)

-2.jpg)

.jpg)

.jpg)

.jpg)

.jpg)