You can learn the recent information of Shijing.

-1.jpg)

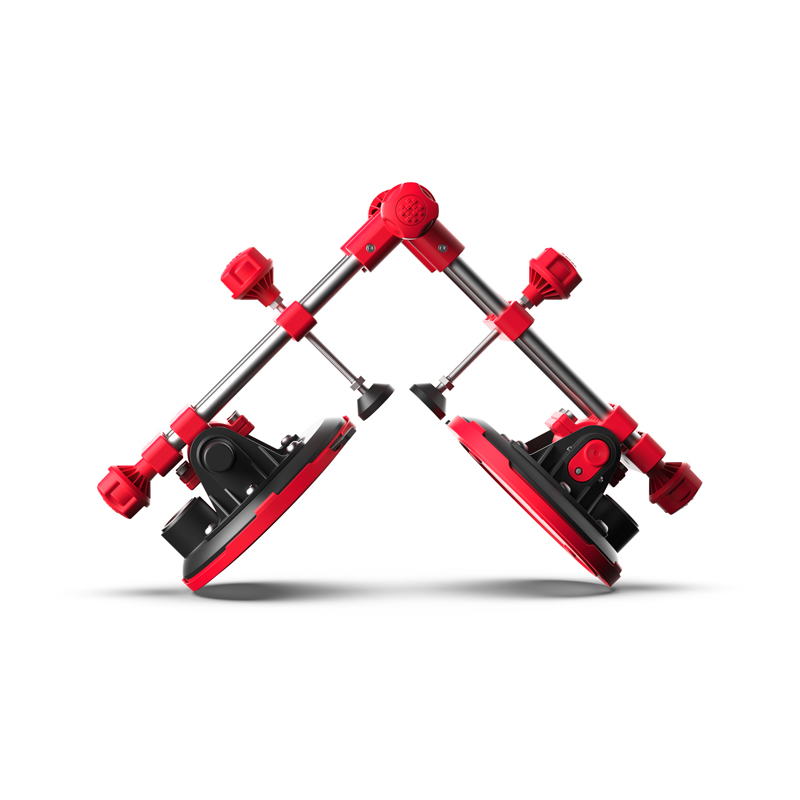

Moving large format tiles—often over 3x5 feet and weighing 50 pounds or more—has long been a persistent challenge for many businesses. The high risk of edge chipping, surface scratching, and even full tile cracking, combined with slow manual handling that drags down project timelines, often creates bottlenecks in work progress. This is where a large-format tile lifting frame comes in. It is a specialised tool engineered specifically to simplify and optimise tile handling, and taking the time to understand its practical value helps businesses make more informed and wise procurement decisions that align with their operational needs.

-1.jpg)

A large-format tile lifting frame focuses on solving the core pain points that plague tile transportation and handling. It adopts a robust, engineered frame structure with adjustable clamping points that hold large tiles securely without applying excessive pressure. This design allows workers to grip and move tiles with significantly less physical effort, reducing fatigue during long workdays. Unlike manual carrying that relies solely on human strength and often cycles to uneven pressure—resulting in cracks, chips, or even drops—this tool distributes the tile's weight evenly across its entire surface. This not only speeds up the handling process by cutting down on time spent adjusting grip or coordinating multiple workers, but also maintains the pristine integrity of tiles from storage to installation. For businesses that process, distribute, or install large tiles, this tool directly addresses the delicate balance between operational efficiency and product protection, two factors that directly impact bottom lines.

This tool is widely applicable across multiple industries that regularly work with large format tiles. In construction sites, workers use a large format tile lifting frame to install floor or wall tiles quickly in high-volume projects like shopping malls, office lobbies, or hotel corridors—where speed and consistency are key. Tile manufacturing factories rely on it to move finished products from production lines to packaging stations or storage areas, eliminating delays caused by careful manual carrying and ensuring a smooth, uninterrupted workflow. Renovation companies also find it indispensable when dealing with large tiles for high-end residential kitchens, bathrooms, or commercial retail spaces, where clients expect flawless tilework. Its ability to adapt to different tile sizes—from standard large tiles (like 24x48 inches) to extra-large slabs (over 6x12 feet)—and compatibility with various tile materials, including ceramic, porcelain, and natural stone, make it a versatile choice for diverse business scenarios.

-1.jpg)

When selecting a large format tile lifting frame, cooperating with reliable large format tile lifting frame manufacturers is crucial for long-term operational success. Trusted manufacturers take the time to understand the specific needs of different industries—whether it's a construction company needing frames for outdoor job sites or a tile factory requiring tools for indoor assembly lines. They can provide products that precisely match the tile sizes, weights, and material types businesses usually handle. For example, some manufacturers offer frames with adjustable width and height components to fit both small and large tiles and oversized slabs, while others add non-slip padding to protect delicate stone surfaces. Experienced manufacturers also have a proven track record of supplying to similar businesses—such as delivering frames to large tile distributors or commercial construction firms—meaning their products have been tested in real-world work environments and can meet the practical operational requirements of busy job sites or factories.

Using a large format tile lifting frame also brings tangible long-term economic benefits that go beyond basic efficiency. It reduces the need for extra labour: instead of assembling a team of three or four workers to carefully carry a single large tile, one or two workers can operate the frame with ease. This cuts down direct labour costs and also reduces the time spent on each handling task, allowing teams to complete more work in a single shift.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

-2.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-4.jpg)