You can learn the recent information of Shijing.

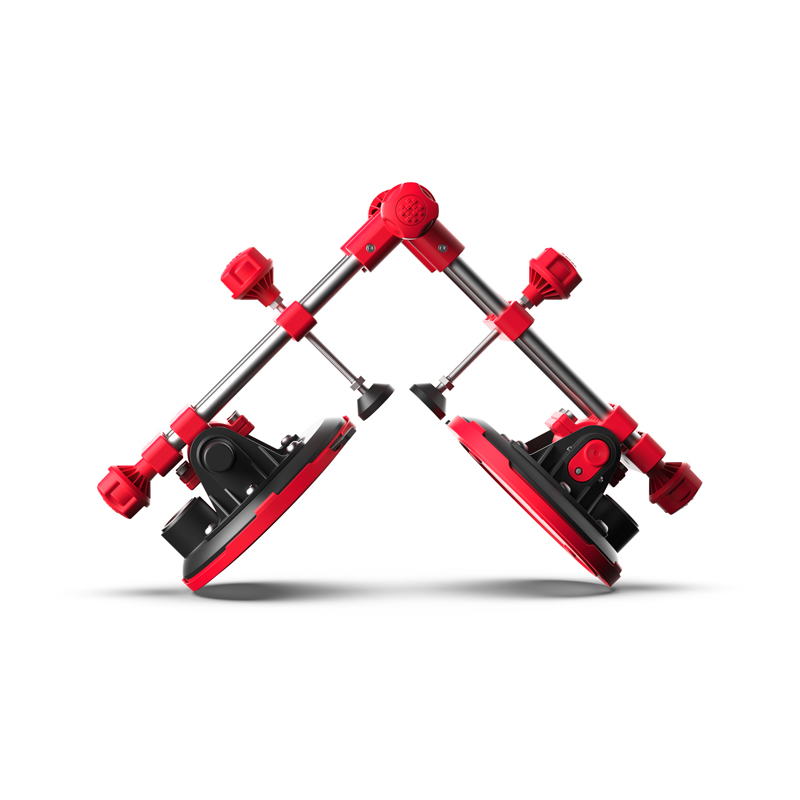

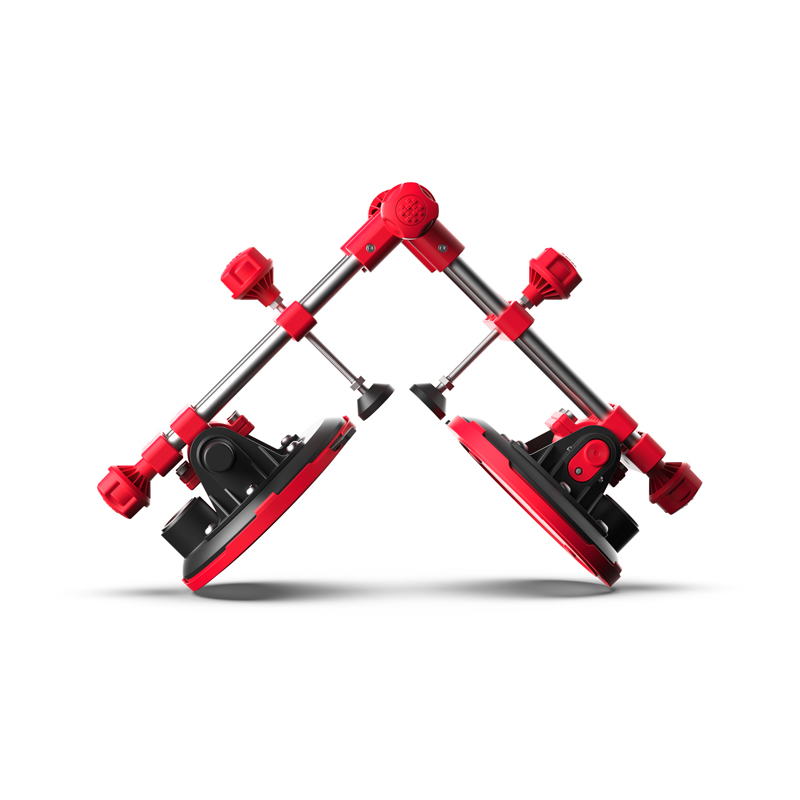

A Heavy Duty Vacuum Suction Cup is often seen as a simple lifting tool, yet many buyers want to understand what actually makes it dependable for industrial work. Behind its straightforward design is a practical solution that supports tasks involving heavy sheets, panels, and smooth-surfaced materials. This tool relies on the vacuum force created by drawing air out of the cup, forming a secure hold that allows the operator to lift and move objects with controlled effort. For companies comparing different handling tools, this option offers a balance between functionality, flexibility, and operational comfort.

Many inquiries from buyers start with one main question: What problems does a Heavy Duty Vacuum Suction Cup solve in daily operations? The answer varies by industry, but it often connects to reducing manual strain, improving handling accuracy, and supporting frequent material transfers. Heavy Duty Vacuum Suction Cup Manufacturers continue to refine load capacity options and handle designs, making the tool adaptable for glass work, stone fabrication, metal processing, automotive repairs, and even marine or aerospace tasks.

1. How It Addresses Common Handling Challenges

Operators often deal with heavy materials that are flat but difficult to grip. Manual lifting increases fatigue and affects productivity. A Heavy Duty Vacuum Suction Cup creates an instant hold without scratching or clamping, which helps reduce the time spent positioning or adjusting the material. For factory teams that handle panels repeatedly, this level of convenience becomes a practical advantage.

At the same time, the vacuum grip supports smoother movements. Whether placing a glass sheet into a frame or shifting a metal plate during assembly, the suction cup offers a stable hold that helps the operator stay in control. This is one reason Heavy Duty Vacuum Suction Cup Manufacturers receive consistent demand from construction, production, and automotive service providers.

2. Why Different Industries Adopt It

Buyers often want to know why this tool appears across so many sectors. Industries that deal with flat, heavy items share similar requirements: reliable handling, reduced workforce strain, and steady grip during positioning. In construction, teams use it to guide glass sheets or stone slabs. In manufacturing, it helps move equipment covers, metal panels, and machine parts. Automotive repair centers often rely on it for windshields, while marine and aerospace workers use it during component placement and maintenance.

The tool's adaptability gives it long-term value. Instead of investing in larger mechanical lifting equipment for moderate-sized tasks, companies choose a Heavy Duty Vacuum Suction Cup because it offers practical lifting force in a compact form. For workshops or job sites with limited storage, this becomes especially useful.

3. Key Features Buyers Usually Look For

When comparing options from Heavy Duty Vacuum Suction Cup Manufacturers, buyers tend to focus on durability, grip performance, and handle comfort. Material quality plays an important role, particularly in the cup's sealing surface. A well-formed seal maintains vacuum pressure longer, which supports steady lifting and reduces interruptions. Many factories also evaluate the pump mechanism or manual trigger design to match it with their operators' preferences.

Another area of interest is the range of sizes and lifting capacities. Since jobs vary from thin glass to dense stone slabs, having the right diameter or weight rating helps buyers avoid mismatched tools. Manufacturers now offer multiple configurations so that users can select the model that fits their workload instead of relying on one universal design.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

-2.jpg)

.jpg)

.jpg)

-1.jpg)

.jpg)