You can learn the recent information of Shijing.

A Tile Cutter is a simple tool glance, yet buyers in construction, renovation, and flooring installations often compare its structure, cutting effect, long-term durability, and handling comfort. Professional users care about how clean the scoring line appears, how stable the base feels during pressure, and whether the cutter can handle long work hours without frequent adjustments. When choosing among different Tile Cutter Manufacturers, many customers search for clear technical descriptions rather than general claims.

A manual Tile Cutter uses a scoring wheel to mark the tile surface, followed by applied pressure that separates the tile along the scored path. Ceramic and porcelain tiles respond differently to the tool, so consistent scoring plays a major role in the cutting outcome. Manual cutters remain popular because they do not require electricity, support fast, straight-line cuts, and are simple to transport across work environments.

1. What structural details matter in a manual Tile Cutter?

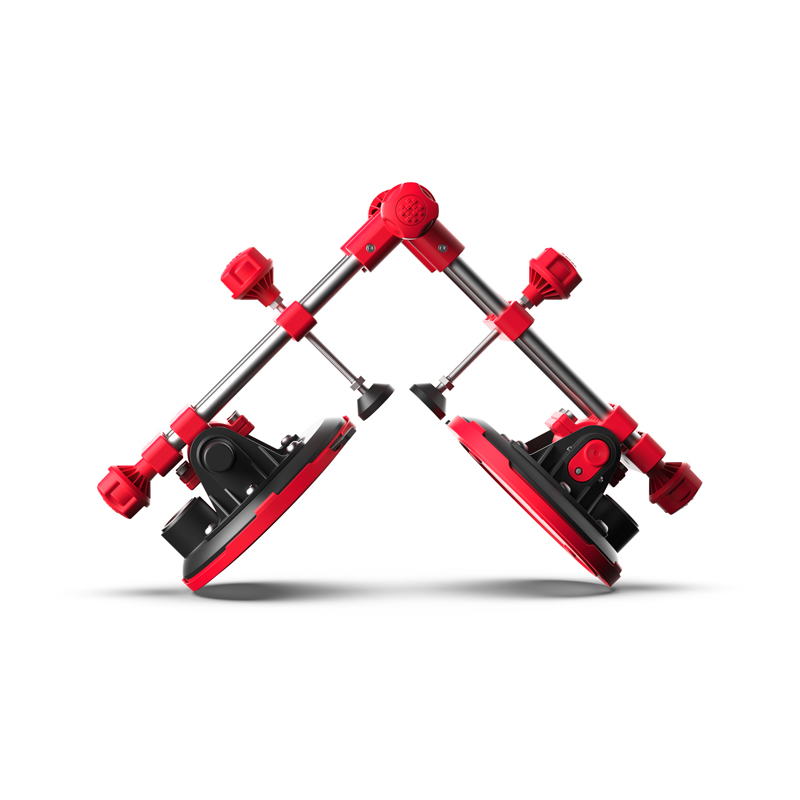

Users often want to know how the base material influences daily operation. An iron base plate provides strong support and weight, which helps during straight-line scoring. This stability reduces vibration and keeps the cutting wheel moving smoothly along the guide rail. Professionals who cut thicker tiles repeatedly tend to appreciate this stable feel.

An aluminium base plate offers a lighter body, which helps technicians who move between rooms or floors during installation work. Corrosion resistance makes aluminium models suitable for long-term storage or humid environments. Both base types usually include measurement markings that guide repetitive cuts without the need for extra tools.

Understanding these differences helps customers choose a model that matches their routine—whether they prioritise portability or stronger support.

2. How do users judge cutting performance in real tasks?

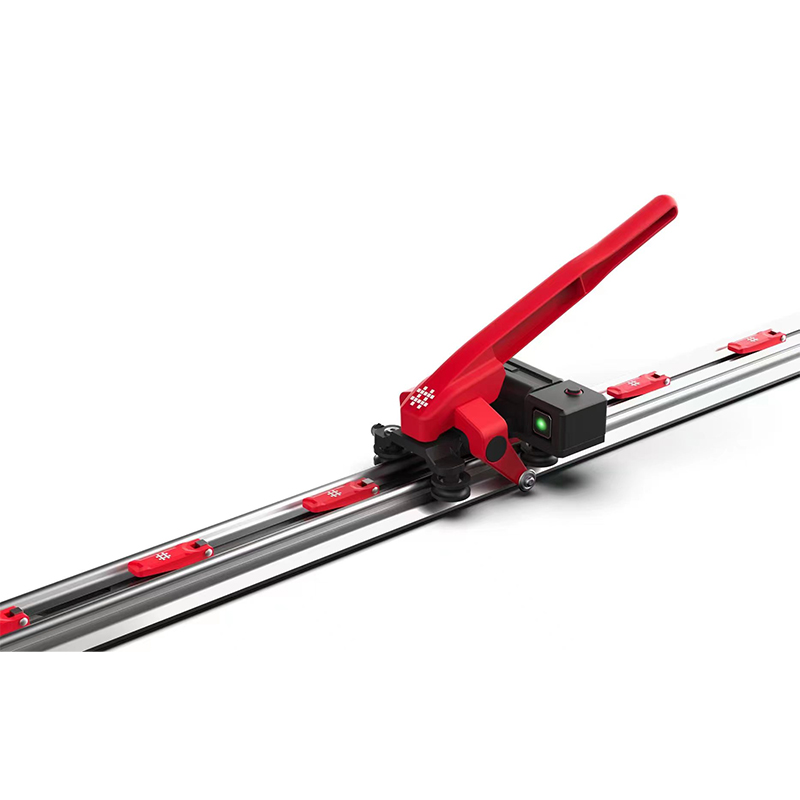

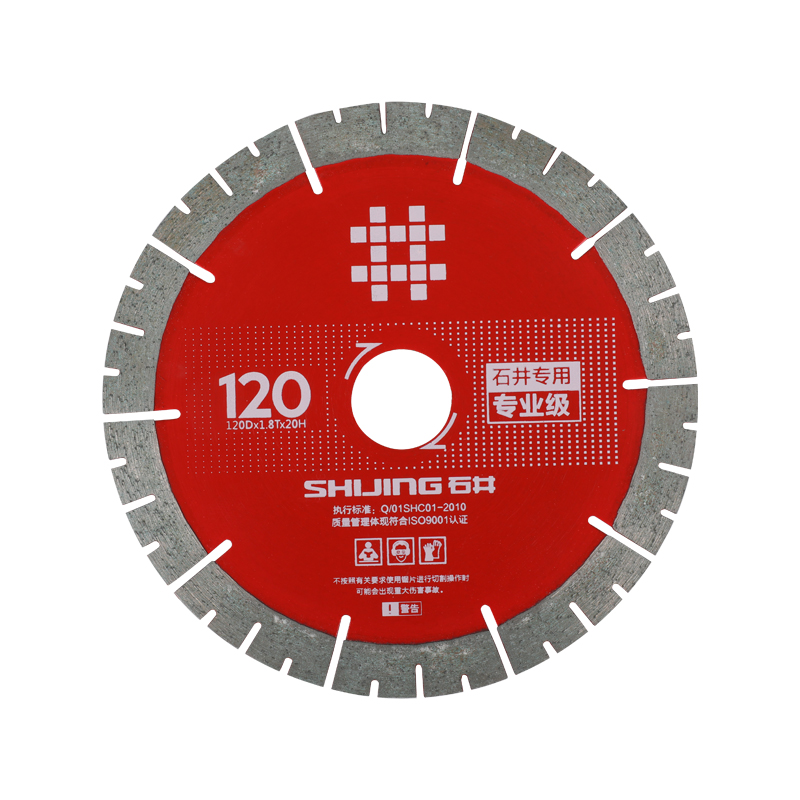

A manual Tile Cutter is expected to score cleanly without creating random cracks. Buyers often pay attention to the cutting wheel material, with tungsten carbide being common for reliable scoring. They want the wheel to glide smoothly along the rail and produce an even line with minimal resistance.

Another concern is snapping pressure. A well-built handle distributes force smoothly so the tile breaks along the correct line without fragmentation. Installers who handle various tile sizes also value a cutter that adapts to different thickness levels without sudden stiffness. These real-use experiences often matter more than pure specification numbers when comparing cutters from various Tile Cutter Manufacturers.

3. How do we compare durability and working comfort?

Professionals working on large flooring projects need a tool that holds alignment even after hundreds of cuts. Iron base models support this need through their solid framework. Aluminium models, though lighter, remain popular because they resist surface wear and are easy to clean in dusty or wet jobsite conditions.

Working comfort is another important consideration. A stable base reduces hand fatigue during repetitive scoring. Users also check whether the guide rail stays straight over time and whether the handle grip feels natural during long sessions. These simple comfort factors often influence long-term satisfaction more than buyers initially expect.

Manufacturers often emphasise the structure, wheel material, and guide rail design. For sourcing, customers expect transparent descriptions of components and clear model differences. Some manufacturers provide optional wheels, reinforced rails, or upgraded brackets that support heavier pressure. Others focus on lighter designs for portable use.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

-2.jpg)

.jpg)

.jpg)

-1.jpg)

.jpg)

.jpg)

-5.jpg)

.jpg)