You can learn the recent information of Shijing.

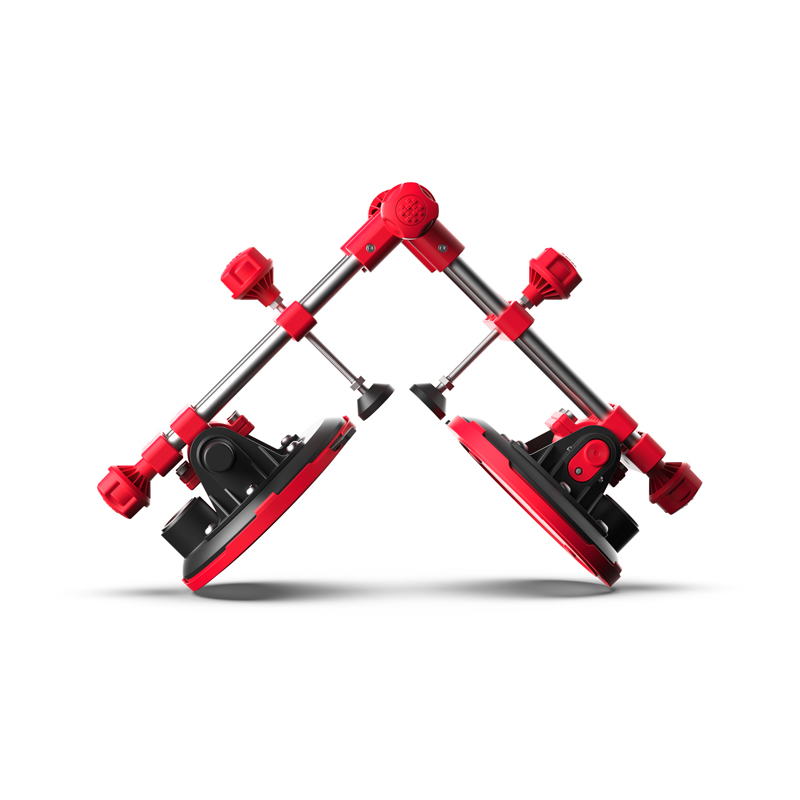

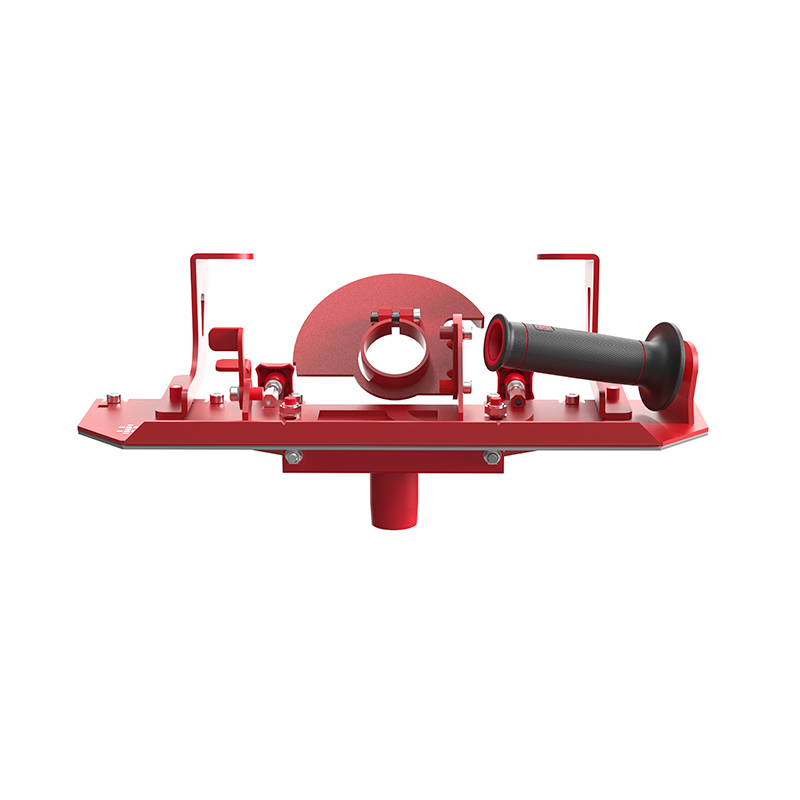

The Heavy Duty Vacuum Suction Cup is a crucial tool across many industries, from construction and manufacturing to automotive repair and logistics. Its ability to securely hold, lift, and transport heavy or fragile materials depends significantly on the design and, importantly, the material of the suction cup itself. This article explores how different materials—such as silicone, rubber, and thermoplastic rubber (TPR)—affect the sealing ability, durability, and overall performance of the Heavy Duty Vacuum Suction Cup.

The Role of Material in Suction Performance

A suction cup's primary function is to create a reliable vacuum seal against a surface. The material composition directly influences how well this seal forms and holds under different conditions. The commonly used materials for Heavy Duty Vacuum Suction Cups include silicone, natural rubber, and TPR, each bringing unique properties.

Silicone suction cups are known for their flexibility and temperature resistance. This makes them ideal for applications where the Heavy Duty Vacuum Suction Cup must endure both high heat and cold environments without losing seal integrity.

Natural rubber offers strong elasticity and grip, making it suitable for smooth and slightly textured surfaces. Rubber-based suction cups in the Heavy Duty Vacuum Suction Cup category are praised for their cost-effectiveness and durability in moderate conditions.

Thermoplastic Rubber (TPR) combines qualities of both rubber and plastic, offering durability, flexibility, and chemical resistance. TPR-based suction cups in the Heavy Duty Vacuum Suction Cup design provide reliable sealing even on uneven or rough surfaces, which often challenge other materials.

Durability and Maintenance Considerations

Durability is another critical factor influenced by suction cup material. The Heavy Duty Vacuum Suction Cup must withstand repeated use, exposure to environmental elements, and mechanical stress without cracking or deforming. Silicone suction cups typically resist aging and UV degradation better than rubber, extending the lifespan of the Heavy Duty Vacuum Suction Cup in outdoor applications.

However, natural rubber suction cups in the Heavy Duty Vacuum Suction Cup lineup perform well indoors and under consistent environmental conditions. Meanwhile, TPR offers a balance of durability and flexibility, often preferred in industrial settings where chemical exposure and surface irregularities occur.

Case Study: Heavy Duty Vacuum Suction Cup in Glass Installation

A glass installation company based in California recently evaluated the performance of various Heavy Duty Vacuum Suction Cups during a high-rise window project. The team tested silicone, rubber, and TPR suction cups for lifting and positioning large glass panels.

The silicone Heavy Duty Vacuum Suction Cups excelled in sealing to the smooth glass surfaces, especially under fluctuating outdoor temperatures. The rubber suction cups, while providing good grip initially, showed slight wear after continuous use, affecting seal reliability. TPR suction cups offered strong adhesion but were preferred for handling glass with slight surface contaminants or textured coatings.

As a result, the company adopted a combination approach—utilizing silicone-based Heavy Duty Vacuum Suction Cups for standard panels and TPR-based suction cups for specialized or textured glass. This strategy improved overall efficiency and reduced suction failures, highlighting how material choice impacts the performance and safety of the Heavy Duty Vacuum Suction Cup.

Industry Implications and Future Trends

Understanding material properties helps industries select the right Heavy Duty Vacuum Suction Cup for specific tasks, reducing downtime and improving safety. Manufacturers are investing in hybrid materials and coatings to further enhance suction cup life and performance.

Moreover, some next-generation Heavy Duty Vacuum Suction Cups integrate sensor technology to monitor vacuum pressure and material wear in real-time, providing proactive maintenance alerts and ensuring consistent operation.

The material used in a Heavy Duty Vacuum Suction Cup plays a vital role in its sealing capability and durability. Silicone, rubber, and TPR each offer distinct advantages and limitations, making them suitable for different applications. By selecting the appropriate material, professionals can optimize the safety, reliability, and efficiency of vacuum suction operations.

As demonstrated by the real-world glass installation case, the right Heavy Duty Vacuum Suction Cup material choice significantly impacts project success. Continued innovation in suction cup materials promises even better performance in the future, supporting the diverse needs of industries worldwide.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

.jpg)

.jpg)

-2.jpg)

.jpg)

-3.jpg)

.jpg)

.jpg)