You can learn the recent information of Shijing.

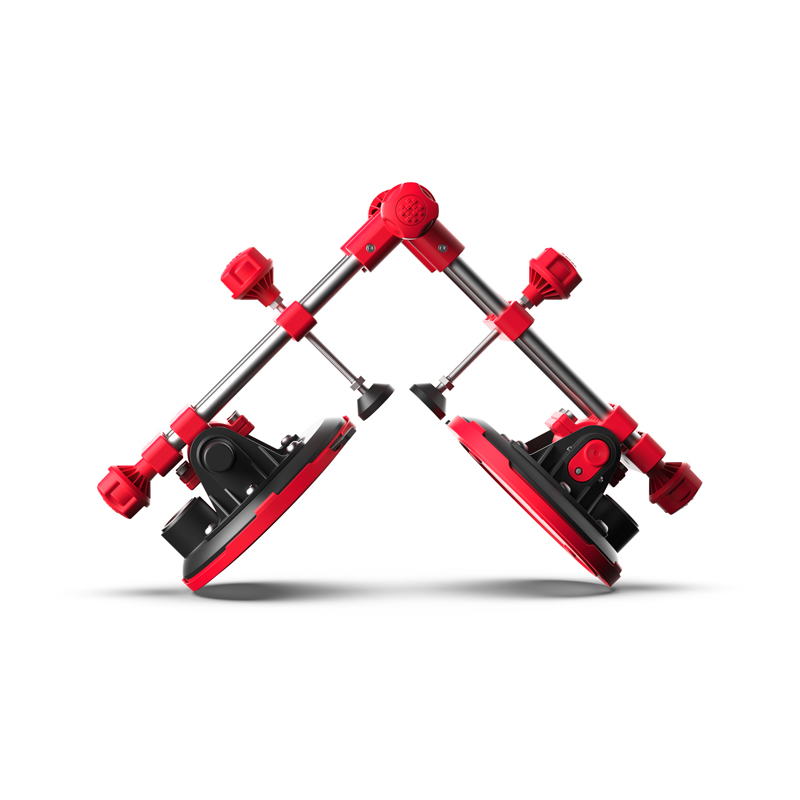

Imagine the sheer mass of a thick steel plate destined for a ship’s hull, a pristine slab of architectural glass taller than a house, or a colossal stone countertop weighing several tons. Traditionally, moving these behemoths relied on clamps, hooks, chains, or complex mechanical rigging methods, often risking damage to precious surfaces, demanding significant manual labor, and posing inherent safety challenges. Enter the Heavy Duty Vacuum Suction Cup: a technological marvel transforming material handling by offering unparalleled strength and a fundamentally gentler, more efficient approach. At its core, the defining power of the Heavy Duty Vacuum Suction Cup lies in its extraordinary ability to securely lift and manipulate objects of immense weight, seamlessly replacing or augmenting conventional, often invasive, techniques.

The term "Heavy Duty" isn't mere marketing hyperbole for these specialized tools; it's a precise engineering specification. Unlike standard suction cups designed for lighter loads, the Heavy Duty Vacuum Suction Cup is meticulously crafted from the ground up to handle forces. Think in terms of hundreds of kilograms extending effortlessly into the realm of multiple tons, even reaching capacities of tens of tons when multiple units are deployed in a synchronized system. This immense holding power isn't accidental; it's the result of:

Robust Construction: Utilizing high-strength engineering polymers, reinforced composites, corrosion-resistant metals like aluminum or stainless steel, and exceptionally durable, high-performance sealing materials (like polyurethane or specialized nitrile rubbers). Every component within the Heavy Duty Vacuum Suction Cup is selected and designed to withstand immense stress without deformation or failure.

Engineered Vacuum Systems: Generating and maintaining the high vacuum levels (-90 kPa and beyond) necessary for such massive loads requires powerful, reliable vacuum pumps or ejectors specifically matched to the Heavy Duty Vacuum Suction Cup. These systems ensure rapid evacuation of air under the cup, creating the powerful atmospheric pressure differential that translates into an immense lifting force.

Optimized Surface Contact: Large-diameter or specially shaped cups maximize the effective sealing area. Combined with sophisticated sealing lip profiles designed to conform to slight surface irregularities, this ensures the Heavy Duty Vacuum Suction Cup achieves the critical seal needed to generate its full theoretical lifting capacity. Redundant internal chambers within larger cups enhance safety, preventing catastrophic drops if one chamber loses its seal.

Beyond Strength: The Transformative Value Proposition

The ability to lift incredibly heavy objects is impressive, but the true revolution delivered by the Heavy Duty Vacuum Suction Cup lies in how it achieves this and the tangible benefits it unlocks across diverse industries. Its core value stems from providing a powerful, non-marring, and versatile grip where traditional methods falter or cause harm:

Handling the Unhandleable (Safely & Efficiently):

Massive Panels: Steel plates in shipyards and fabrication plants, oversized glass panes for skyscrapers or high-end facades, thick acrylic sheets, complex composite structures in aerospace – the Heavy Duty Vacuum Suction Cup provides a secure, distributed grip over large surface areas. This eliminates the need for dangerous edge clamping or piercing methods that can distort or damage expensive materials. A system built around multiple Heavy Duty Vacuum Suction Cups can effortlessly maneuver panels weighing many tons with precision.

Monolithic Stone & Concrete: Granite countertops, marble slabs, large prefabricated concrete elements, and heavy masonry blocks are notoriously difficult to grip securely without risk of chipping or breakage. The Heavy Duty Vacuum Suction Cup applies uniform lifting force across the surface, significantly reducing stress points and minimizing the risk of damage inherent with slings or clamps.

Industrial Giants: Massive molds for injection molding or die-casting, heavy machinery components, large-diameter pipes, and even standard shipping containers. The Heavy Duty Vacuum Suction Cup offers a versatile solution for lifting, positioning, and transporting these awkward, heavy items without the need to attach hooks or rig complex slinging arrangements. A strategically placed Heavy Duty Vacuum Suction Cup system simplifies logistics dramatically.

Replacing Traditional Rigging: A Safer, Smoother Alternative:

Eliminating Surface Damage: Hooks scratch, clamps dent, and chains abrade. The Heavy Duty Vacuum Suction Cup grips solely through vacuum force applied to a clean, flat(ish) surface, leaving sensitive materials like polished metal, coated surfaces, glass, or finished stone completely unmarked. This preservation of material integrity is a major cost saver and quality assurance factor.

Enhanced Safety: Rigging heavy loads with chains or slings requires skilled labor and carries inherent risks of slippage, sudden load shifts, or failure points. A properly applied Heavy Duty Vacuum Suction Cup system provides a more stable, distributed hold. Integrated vacuum monitoring and safety valves provide critical feedback and redundancy, significantly reducing the risk of accidental drops compared to purely mechanical methods. The Heavy Duty Vacuum Suction Cup inherently offers a safer working environment when handling massive objects.

Operational Efficiency: Setting up traditional rigging is time-consuming. Deploying a Heavy Duty Vacuum Suction Cup system is often dramatically faster – position the cup(s), initiate vacuum, and lift. This speed translates directly into improved workflow, reduced crane time, and faster project completion. The simplicity and speed of using a Heavy Duty Vacuum Suction Cup are key productivity drivers.

Accessibility & Ergonomics: Gripping from the top surface provides access advantages over edge-clamping methods, especially for large panels. Furthermore, it often allows for better operator positioning away from pinch points and falling hazards associated with traditional rigging underneath loads. The Heavy Duty Vacuum Suction Cup enables handling from safer, more ergonomic positions.

The Indispensable Partner for Modern Heavy Industry

From the soaring glass atriums defining modern architecture to the colossal steel structures forming the backbone of infrastructure, and the precision molds shaping consumer goods, the Heavy Duty Vacuum Suction Cup is an indispensable, often unseen, workhorse. It represents a fundamental shift in heavy material handling, moving away from brute force methods that risk damage and danger towards intelligent, reliable, and surface-friendly technology. The Heavy Duty Vacuum Suction Cup delivers on the critical promise of immense strength, but its true genius lies in enabling the safe, efficient, and damage-free manipulation of the world's heaviest and valuable objects, revolutionizing workflows and setting new standards for capability and care in industrial settings. When the task involves moving the immovable, the engineered power and gentle grip of the Heavy Duty Vacuum Suction Cup provide the solution. Investing in a robust Heavy Duty Vacuum Suction Cup system is investing in safety, efficiency, and the preservation of valuable assets.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

-2.jpg)

.jpg)

.jpg)

-1.jpg)

.jpg)

-1.jpg)

.jpg)

-3.jpg)

.jpg)