You can learn the recent information of Shijing.

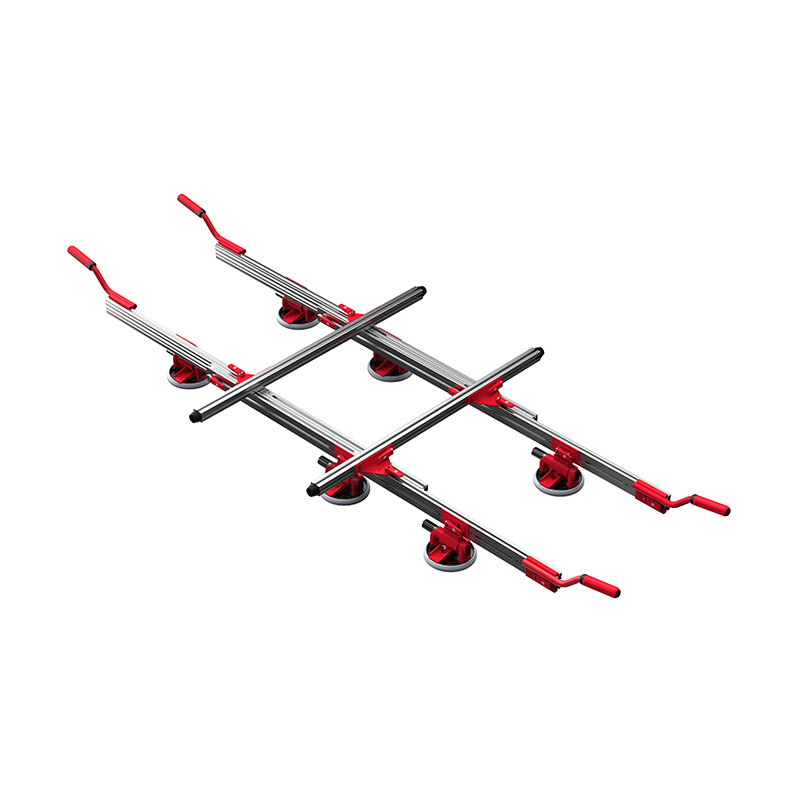

In industrial and professional settings, handling large, heavy, or delicate materials requires not only strength but also precision. Whether it’s moving glass panels, brushed stainless steel, or textured stone slabs, the one component that often makes or breaks performance is the suction system. Among the tools relied on for such tasks, the Heavy Duty Vacuum Suction Cup plays a critical role, and its sealing performance is central to its effectiveness.

Built for Real-World Surfaces

When engineers design a Heavy Duty Vacuum Suction Cup, the challenge isn't just how firmly it grips a perfectly smooth surface. Real-world surfaces are rarely perfect. Many materials have subtle textures, fine grooves, or even light contamination from dust or oil. This is where sealing performance comes into play — and where the Heavy Duty Vacuum Suction Cup separates itself from weaker alternatives.

What sets the Heavy Duty Vacuum Suction Cup apart is its ability to maintain a consistent vacuum seal even when the surface isn’t flawlessly smooth. This is made possible by its high-quality sealing lip, often crafted from materials such as polyurethane, nitrile rubber (NBR), or silicone. These compounds are selected for their flexibility, wear resistance, and adaptability to surface irregularities.

Flexible Yet Firm: The Ideal Seal

The seal formed by a Heavy Duty Vacuum Suction Cup needs to be both soft enough to conform to slight variations and firm enough to hold pressure under load. A well-engineered sealing lip adjusts subtly to fine scratches, brushed textures, or minimally oily surfaces. This is not just a convenience — it’s a functional requirement in environments where quick, repeated use on different materials is common.

For instance, lifting brushed stainless steel, which has a directionally rough surface, can be a challenge for basic suction tools. But a Heavy Duty Vacuum Suction Cup with an adaptive sealing material will conform to those micro-textures, creating a vacuum seal that holds reliably. This reduces the risk of drops, improves the consistency of the lift, and enhances overall workplace safety.

Energy Efficiency Through Better Sealing

One of the lesser-discussed benefits of sealing performance is improved energy efficiency. A Heavy Duty Vacuum Suction Cup that seals well requires less frequent vacuum regeneration. This translates into lower energy consumption for air-powered systems and less strain on mechanical pumps. Over time, this can to measurable operational savings, especially in production lines where dozens of suction cups operate continuously.

When a poor seal causes even minor vacuum leakage, it forces the system to work harder to maintain pressure. By eliminating those tiny leaks, the Heavy Duty Vacuum Suction Cup not only improves performance but also reduces wear on associated equipment like pumps and valves.

Adaptability Across Surfaces

Another significant value offered by a Heavy Duty Vacuum Suction Cup with sealing performance is its versatility across materials. In the construction, automotive, and manufacturing industries, it's common to handle a wide variety of surface types — from matte-finished stone tiles to slightly oily sheet metal. The ability of a single tool to perform reliably across all these applications is a major operational advantage.

Thanks to the sealing lip’s flexibility and resilience, the Heavy Duty Vacuum Suction Cup can maintain grip where other tools fail. This reduces the need for multiple specialized devices and streamlines processes on the shop floor.

Durability Without Compromise

While softness and flexibility are key to sealing performance, they don’t come at the cost of durability. A well-designed Heavy Duty Vacuum Suction Cup balances wear resistance with adaptability. The materials used in its sealing lip resist aging, deformation, and degradation even under repetitive use.

This durability ensures that the sealing integrity remains consistent over time, meaning fewer replacements, less downtime, and more confidence on every lift. Operators can trust that each use of the Heavy Duty Vacuum Suction Cup will deliver the same level of performance, even in demanding conditions.

A Small Detail That Makes a Big Difference

In lifting and handling applications, the small ring of material around the edge of a suction cup might not look like much, but it’s doing all the heavy lifting when it comes to sealing. The sealing ability of the Heavy Duty Vacuum Suction Cup is not just a technical detail; it’s the foundation of safer, more efficient, and more reliable performance.

From textured metal panels to lightly soiled stone surfaces, the Heavy Duty Vacuum Suction Cup adapts to the imperfections of the real world. Its sealing performance supports a cleaner vacuum hold, reduced energy consumption, and broader application use. For professionals who rely on suction-based lifting, this tool offers more than strength — it offers assurance.

Whether you’re on a construction site, in a factory, or working with specialized equipment, the Heavy Duty Vacuum Suction Cup is built to perform where it counts most: at the seal.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

.jpg)

-2.jpg)

.jpg)

.jpg)

.jpg)