You can learn the recent information of Shijing.

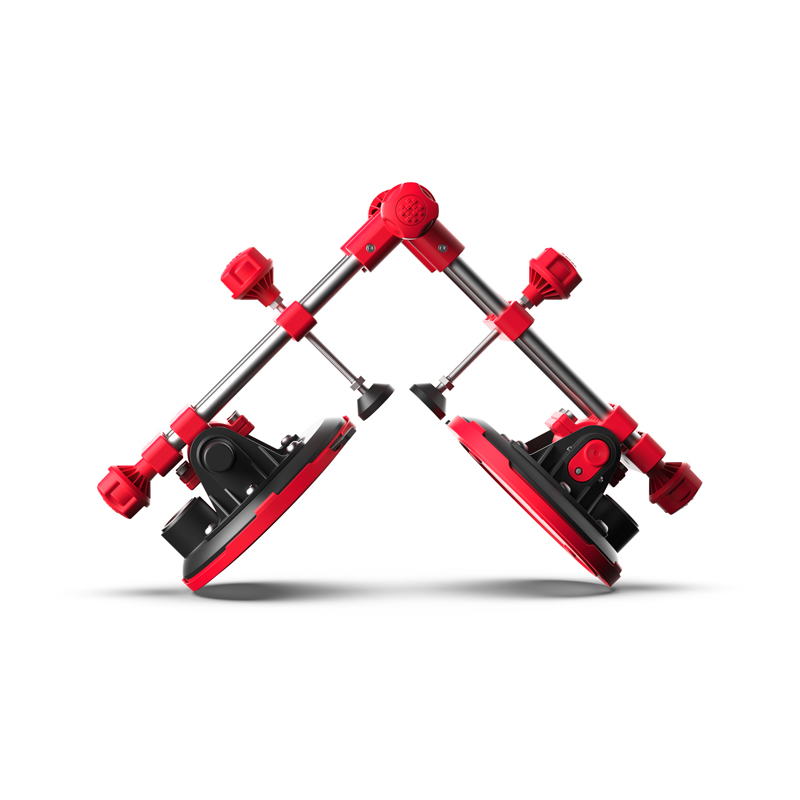

In the intricate choreography of modern industrial automation, where precision, reliability, and speed are paramount, the 200mm Vacuum Suction Cup has emerged as a remarkably versatile and frequently deployed performer. This specific size, striking a balance between substantial lifting capacity and manageable footprint, is becoming a standardized solution across diverse sectors, quietly revolutionizing how objects are handled, transported, and processed.

The prevalence of the 200mm Vacuum Suction Cup isn't accidental. Its 200mm diameter offers a significant surface area for vacuum generation. This translates directly to impressive holding force, capable of securely managing a wide array of moderately heavy and large items, from sizable sheet metal and robust panels to substantial crates and appliance components. Yet, unlike much larger cups, the 200mm Vacuum Suction Cup retains a degree of flexibility and spatial efficiency. It fits comfortably within the tooling of many robots and automated handling systems without requiring excessive redesign or space allocation. This combination of strength and practicality makes the 200mm Vacuum Suction Cup a frequent choice for engineers designing new systems or upgrading existing ones. The consistent performance profile of the 200mm Vacuum Suction Cup allows for predictable results in demanding production schedules.

Why does the 200mm dimension resonate so strongly? Consider applications in logistics and packaging: moving large boxes, sacks, or bundled goods. A single 200mm Vacuum Suction Cup often provides sufficient grip, simplifying end-of-arm tooling compared to needing multiple smaller cups. In construction material handling, items like sheetrock, large tiles, or pre-fabricated panels frequently find a reliable partner in the 200mm Vacuum Suction Cup. Its scale matches the task efficiently. Even within manufacturing plants, transferring appliance doors, oven panels, or sizable machine covers becomes significantly smoother with the consistent hold of a 200mm Vacuum Suction Cup. The inherent stability offered by the 200mm Vacuum Suction Cup minimizes swing or slippage during rapid transfers. For tasks involving flat, relatively smooth surfaces of a moderate scale, the 200mm Vacuum Suction Cup delivers a compelling blend of simplicity and effectiveness. Its capacity often aligns well with the weight of commonly handled industrial items, making the 200mm Vacuum Suction Cup a workhorse component.

The effectiveness of any vacuum cup, including the ubiquitous 200mm Vacuum Suction Cup, hinges significantly on its material composition. Manufacturers offer these cups in various elastomers to suit specific environmental and surface challenges:

Nitrile Rubber (NBR): A common choice for general-purpose applications involving the 200mm Vacuum Suction Cup, offering good abrasion resistance, oil resistance, and durability at a moderate cost. Many standard 200mm Vacuum Suction Cup units utilize NBR.

Silicone: Essential for temperature applications (both high and low) and crucial in food, pharmaceutical, or cleanroom settings due to its inert properties. Silicone 200mm Vacuum Suction Cups provide compliance on slightly uneven surfaces. When hygiene is paramount, the silicone 200mm Vacuum Suction Cup is frequently specified.

Polyurethane (PU): Known for exceptional wear resistance, tear strength, and resilience against cutting or piercing, making PU 200mm Vacuum Suction Cups ideal for handling materials with sharp edges or burrs, such as metal sheets or stamped parts. The durability of a PU 200mm Vacuum Suction Cup extends service life significantly.

Specialty Compounds: Including materials resistant to specific chemicals, conductive grades for handling sensitive electronics (ESD), or fluorosilicone for unique chemical resistance. These specialized 200mm Vacuum Suction Cups address niche but critical requirements.

Selecting the right material for the 200mm Vacuum Suction Cup is vital for performance and lifespan, directly impacting system uptime and operating costs. The versatility of the 200mm Vacuum Suction Cup size is amplified by this range of available materials.

The 200mm Vacuum Suction Cup finds its place in countless scenarios:

Automotive Manufacturing: Lifting and positioning car body panels, interior trim pieces, glass sunroofs, or large battery packs. The 200mm Vacuum Suction Cup provides the necessary force and stability for precise placement in high-volume lines. Robots equipped with 200mm Vacuum Suction Cups handle doors or hoods efficiently.

Sheet Metal Fabrication: Handling steel, aluminum, or composite sheets during cutting, bending, punching, or transfer operations. The 200mm Vacuum Suction Cup, often in PU, withstands sharp edges. Stacks of sheet metal are reliably separated and positioned using robust 200mm Vacuum Suction Cups.

Glass and Glazing: Moving large panes of glass for windows, shower enclosures, or architectural installations. Silicone 200mm Vacuum Suction Cups offer a secure, non-marking grip essential for flawless glass handling. The scale of the 200mm Vacuum Suction Cup matches many standard window sizes effectively.

Packaging and Palletizing: Lifting filled boxes, bags, or bundled products onto pallets or conveyors. The 200mm Vacuum Suction Cup offers sufficient grip for many common package sizes, simplifying automation. A single 200mm Vacuum Suction Cup can often handle a box where smaller cups would require multiples.

Plastics Processing: Handling injection-molded parts, plastic sheets, or large containers. The 200mm Vacuum Suction Cup accommodates the often larger footprint of molded items like bins or appliance housings. Consistent de-molding is aided by reliable 200mm Vacuum Suction Cups.

Food Processing (using compliant silicone cups): Handling large blocks of cheese, bags of ingredients, or packaged food trays where hygiene is critical. The silicone 200mm Vacuum Suction Cup meets stringent safety requirements. Gentle yet secure handling is achieved with the appropriately sized 200mm Vacuum Suction Cup.

Considerations for Implementation

Successfully integrating a 200mm Vacuum Suction Cup requires attention to detail:

Surface Compatibility: While versatile, the 200mm Vacuum Suction Cup requires a reasonably smooth, non-porous surface for vacuum seal. Textured or highly porous surfaces may necessitate specialized cup designs or smaller, multi-cup arrays.

Vacuum Supply: Adequate vacuum flow and holding capacity must be ensured. A larger cup like the 200mm Vacuum Suction Cup demands sufficient pump performance to achieve and maintain the seal quickly, especially in fast cycles. The volume of the 200mm Vacuum Suction Cup cavity influences evacuation time.

Tooling Design: The mounting and articulation of the 200mm Vacuum Suction Cup on the end-effector must allow for proper approach, contact, and release. Weight distribution and potential part flexing need consideration. The physical size of the 200mm Vacuum Suction Cup influences the overall tool design footprint.

Maintenance: Regular inspection of the 200mm Vacuum Suction Cup for wear, cuts, or material degradation is essential to prevent unexpected failures and maintain consistent performance. Proactive replacement of worn 200mm Vacuum Suction Cups ensures reliability.

The Enduring Value of a Standard

In a landscape of constant technological advancement, the 200mm Vacuum Suction Cup demonstrates the enduring value of a well-chosen standard. Its specific dimensions offer a powerful solution that addresses a broad swathe of material handling challenges common in modern industry. By delivering reliable holding force, operational flexibility, and proven performance across diverse environments, the 200mm Vacuum Suction Cup has secured its place as a fundamental component driving efficiency and automation on factory floors and warehouses worldwide. It represents a pragmatic convergence of physics, engineering, and practical need – a testament to the power of getting the size just right. When evaluating options for handling substantial, moderately sized items, the capabilities of the 200mm Vacuum Suction Cup consistently merit serious consideration, proving that sometimes, standardization truly is the key to streamlined operations.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

.jpg)

-2.jpg)

.jpg)

-1.jpg)

-5.jpg)

.jpg)