You can learn the recent information of Shijing.

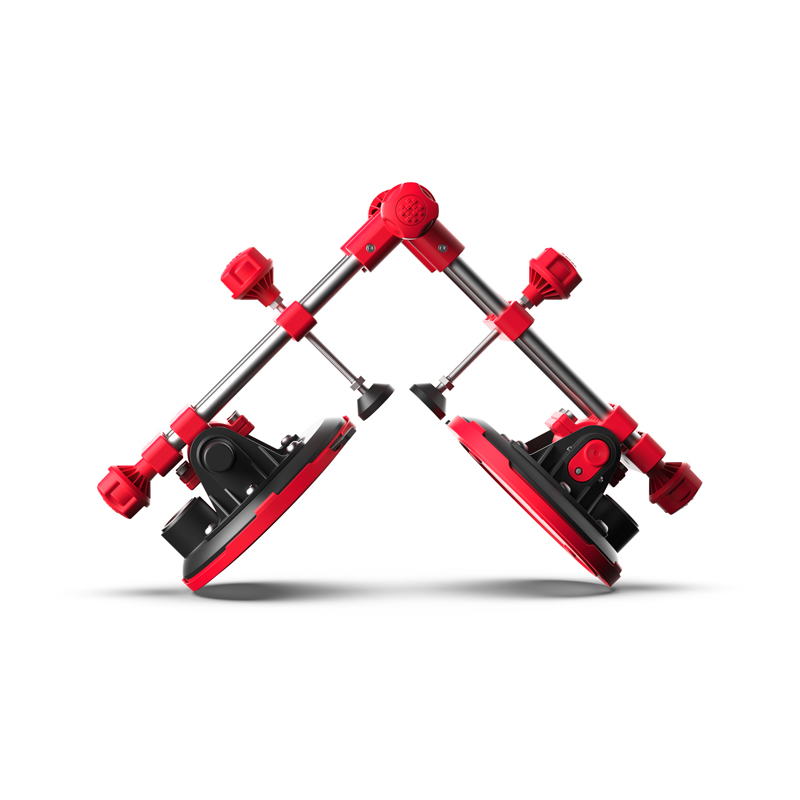

Every day in factories, workshops, and construction sites, there's one common challenge-how to move heavy, smooth materials safely and efficiently. That's where a Vacuum Suction Cup steps in. It's a tool that looks simple but carries an impressive load of engineering behind it. People often wonder how something that small can lift large pieces of glass, metal sheets, or panels with such confidence. The secret lies in the power of air pressure and thoughtful design from skilled Vacuum Suction Cup Manufacturers.

A Vacuum Suction Cup works by removing air between the cup and the surface it's attached to, creating a vacuum that holds the object tightly. When the air is removed, atmospheric pressure outside the cup pushes the surface and cup together-creating a strong grip without any physical hooks or clamps. This makes it ideal for handling materials that shouldn't be scratched, dented, or marked.

Durability is another key concern for users. No one wants a suction cup that loses power after a few months. This is where material quality shows its value. Take Buna-N rubber, for instance. It's widely used in industrial-grade suction cups for its ability to resist wear and maintain flexibility over time. A working life of around two years for the rubber component means it's built for regular use without constant replacement.

Users also ask about strength-how much weight can these tools handle? A professional-grade Vacuum Suction Cup with a 200mm rubber diameter can handle vertical loads up to around 140 kilograms. That's enough to lift large glass panes or metal sheets with confidence. The combination of strong suction, sturdy rubber, and smart engineering allows workers to move heavy materials without strain or risk.

One of the lesser-known advantages of these tools is how they improve workflow. By reducing manual effort, they help workers stay efficient and reduce fatigue. Imagine trying to carry a smooth, heavy glass panel by hand-it's tiring and dangerous. Using a suction cup turns that task into a quick and steady lift. This simplicity is exactly what Vacuum Suction Cup Manufacturers focus on-creating solutions that blend ease, reliability, and safety.

Maintenance is straightforward, too. Keeping the rubber surface clean and smooth helps maintain suction strength. Users only need to check the cup for cracks or wear and make sure the air pump works properly. With regular care, these tools perform consistently over their service life.

From a manufacturing perspective, each detail matters-the size of the rubber, the structure of the pump, the pressure balance, and even the grip design for the operator's comfort. That attention to detail separates experienced Vacuum Suction Cup Manufacturers from the rest. Their designs come from years of trial, feedback, and constant improvement based on how workers actually use the tools.

At its core, the Vacuum Suction Cup is a simple idea made powerful through precision. It shows how practical engineering can make tough jobs easier and safer. For professionals handling glass, metal, or other smooth materials, it's more than just a tool-it's a reliable helping hand. Whether it's a single suction cup or a larger lifting system, the goal remains the same: secure grip, steady movement, and effortless control.

That's why this humble yet clever tool continues to be a quiet star in many industries. Behind every strong suction and secure lift, there's thoughtful design and reliable craftsmanship from dedicated Vacuum Suction Cup Manufacturers-making work lighter, faster, and more confident every single day.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

-2.jpg)

.jpg)

.jpg)

-1.jpg)

.jpg)

.jpg)