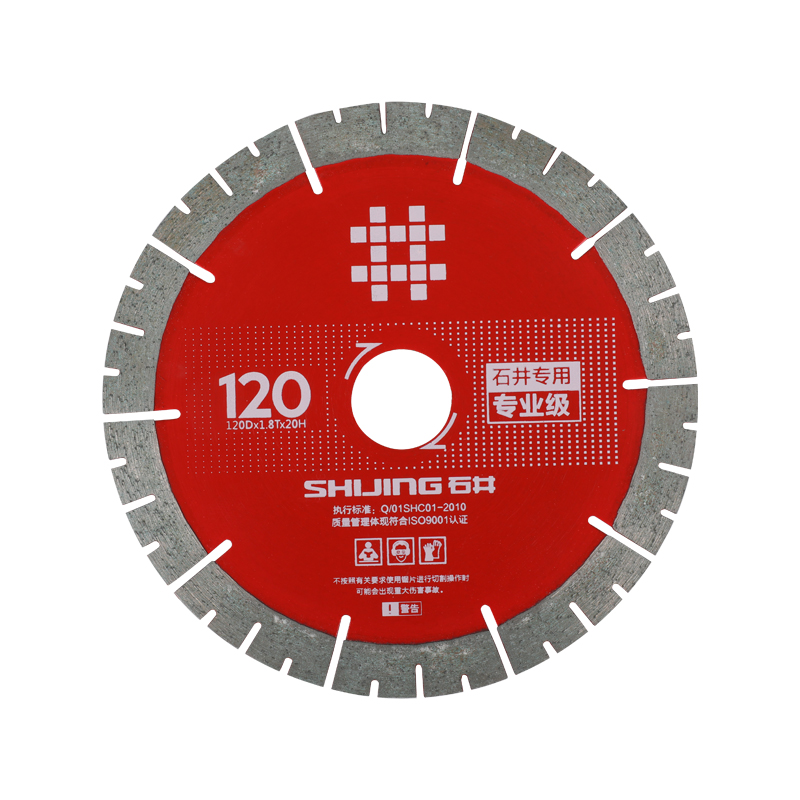

You can learn the recent information of Shijing.

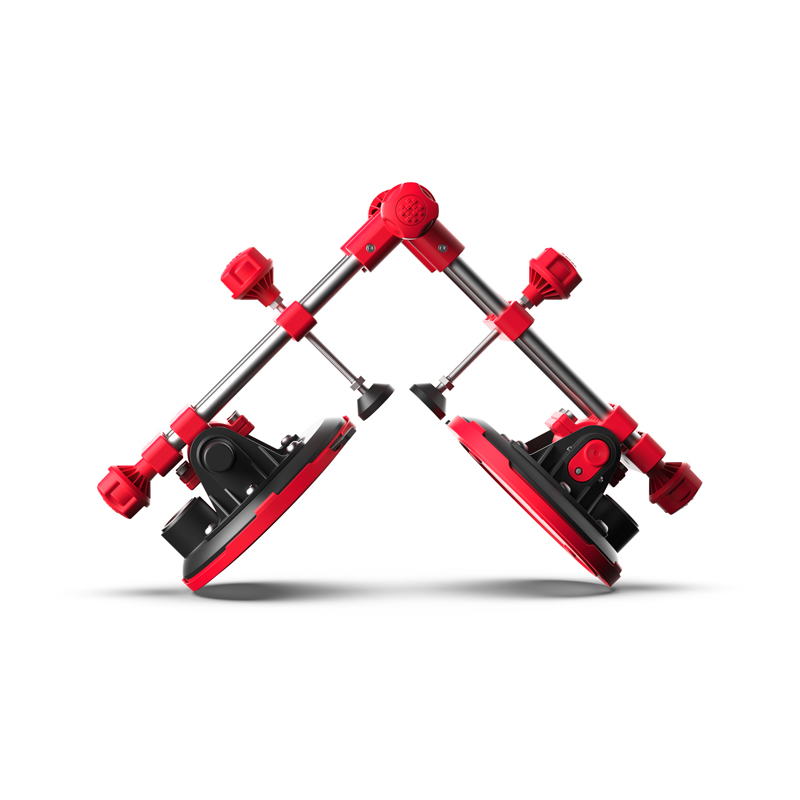

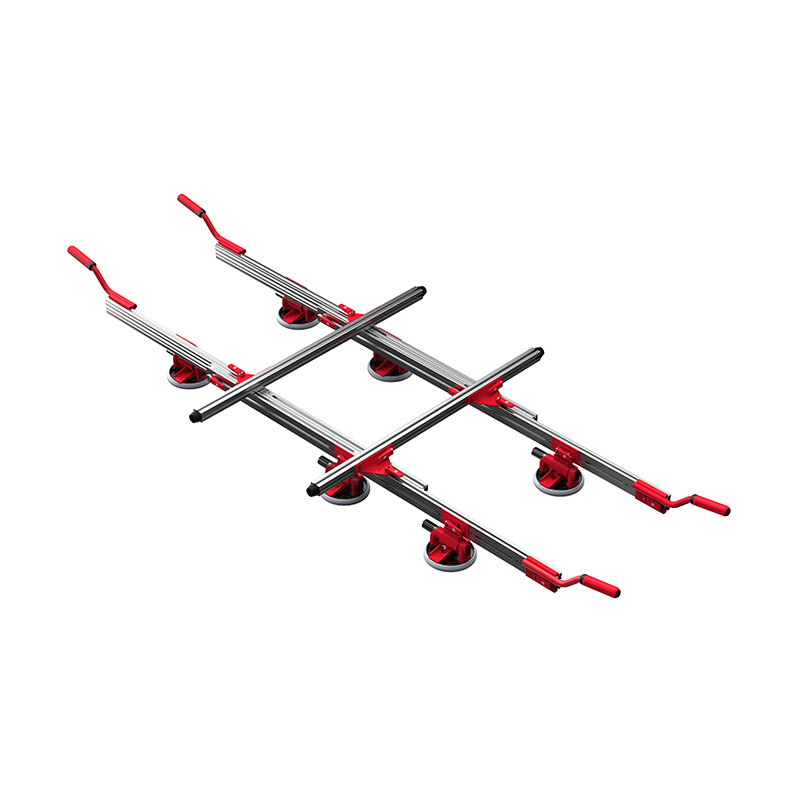

In industries where safe and efficient handling of heavy, delicate, or oversized materials is essential, the Heavy Duty Vacuum Suction Cup has become a staple tool. From glass installation to metal fabrication and tile lifting, the right Heavy Duty Vacuum Suction Cup can significantly reduce manual strain, minimize breakage, and improve worksite efficiency. However, selecting the right model isn’t just about grabbing the strongest option available. Factors such as load capacity, surface compatibility, frequency of use, and safety lock design must all be considered to ensure effective performance.

Load Capacity: Know Your Weight Requirements

The critical factor in choosing a Heavy Duty Vacuum Suction Cup is understanding how much weight it needs to hold. Suction cups are typically rated by load capacity under ideal conditions—flat, clean, non-porous surfaces. For example, a Heavy Duty Vacuum Suction Cup rated for 150 kg may not safely hold the same weight on a vertical or uneven surface.

When selecting a Heavy Duty Vacuum Suction Cup, always factor in a safety margin. If you're lifting a 100 kg object, consider choosing a model rated for at least 150 kg. For larger panels or heavier materials, dual- or multi-cup configurations may be required to distribute the load more evenly.

Contact Surface: Smooth, Rough, or Porous?

Not all surfaces are created equal, and the Heavy Duty Vacuum Suction Cup must match the surface texture and material. These tools perform on smooth, flat surfaces such as glass, polished stone, or finished metal. For slightly rough or curved surfaces, specialized Heavy Duty Vacuum Suction Cup designs with flexible edges or deeper cup profiles can offer improved sealing.

Avoid using standard Heavy Duty Vacuum Suction Cups on porous surfaces like untreated wood or textured tile, as maintaining suction will be difficult or impossible. In these cases, alternative lifting methods or surface treatments may be necessary before using suction equipment.

-3.jpg)

Usage Frequency: Occasional Tasks vs Daily Operations

The expected frequency of use plays a major role in selecting the right Heavy Duty Vacuum Suction Cup. For occasional tasks such as seasonal window replacement or one-off furniture moves, a manual suction cup with a simple plunger mechanism may suffice. However, in high-frequency environments like manufacturing lines or professional installation crews, investing in a Heavy Duty Vacuum Suction Cup with enhanced durability, replaceable parts, and reinforced components is strongly advised.

Frequent users should also look for wear-resistant materials and user-friendly features such as pressure indicators or easy-release handles to reduce fatigue over time.

Safety Lock Design: An Added Layer of Protection

Safety should never be an afterthought when handling heavy or fragile objects. A well-designed Heavy Duty Vacuum Suction Cup will include some form of safety lock or visual indicator to ensure the cup is securely sealed before lifting begins. This feature is especially critical when operating on vertical planes or at heights, where a sudden loss of suction could have costly or dangerous consequences.

Look for Heavy Duty Vacuum Suction Cups with secondary locking levers or vacuum gauges that visually confirm secure attachment. Some advanced models even come with audible alerts if suction drops below safe levels, giving operators an extra layer of control.

Choosing the right Heavy Duty Vacuum Suction Cup is more than a technical decision—it’s a matter of safety, productivity, and protecting the integrity of the materials you handle. By evaluating key factors such as load capacity, surface type, usage frequency, and safety mechanisms, professionals can ensure they are using the appropriate Heavy Duty Vacuum Suction Cup for each job.

In an increasingly precision-driven work environment, having the right Heavy Duty Vacuum Suction Cup on hand is not just helpful—it’s essential.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

.jpg)

-2.jpg)

.jpg)

.jpg)

.jpg)