You can learn the recent information of Shijing.

Renovating a space often means confronting the ceiling—a daunting task when faced with heavy, fragile tiles suspended high above. For decades, the process relied on ladders, precarious balancing acts, straining muscles, and the ever-present risk of damaging tiles or causing injury. Enter the Tile Lifting Frame, a deceptively simple yet profoundly impactful tool changing the game for contractors, facility managers, and ambitious DIYers tackling suspended ceilings. Companies like Shijing Tools, innovators in practical construction solutions, recognize the critical role this specialized equipment plays in modern, efficient renovation.

Safely removing or installing large, often brittle ceiling tiles without breakage or accidents, especially when working at height. Traditional methods involving ladders and manual support are not only slow and physically taxing but also inherently risky. A single slip, an awkward angle, or uneven pressure can to cracked tiles, project delays, increased costs, and potential worker injury. This is precisely where the Tile Lifting Frame proves its worth as an indispensable asset.

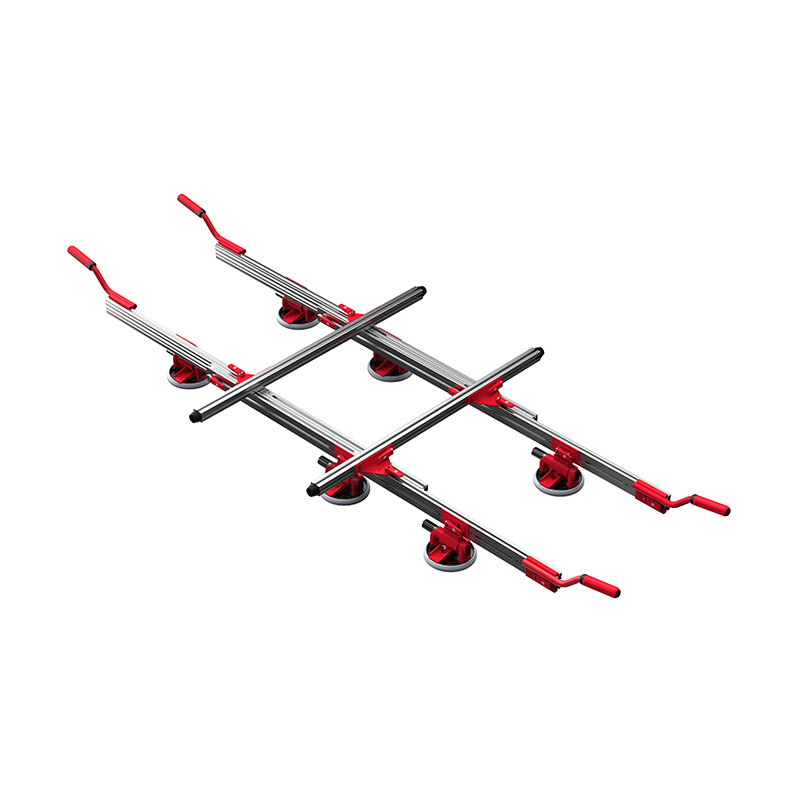

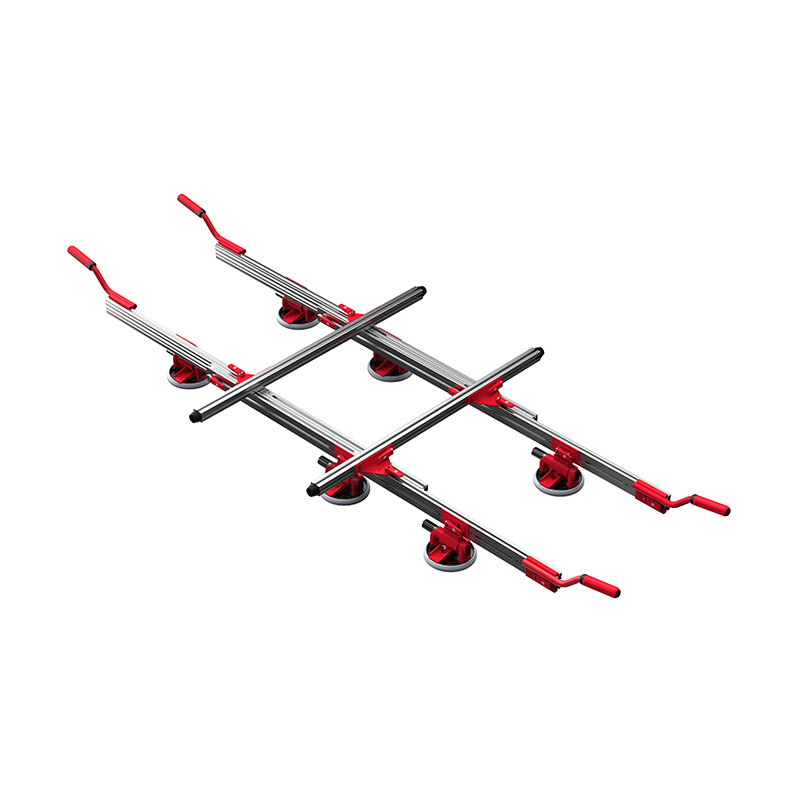

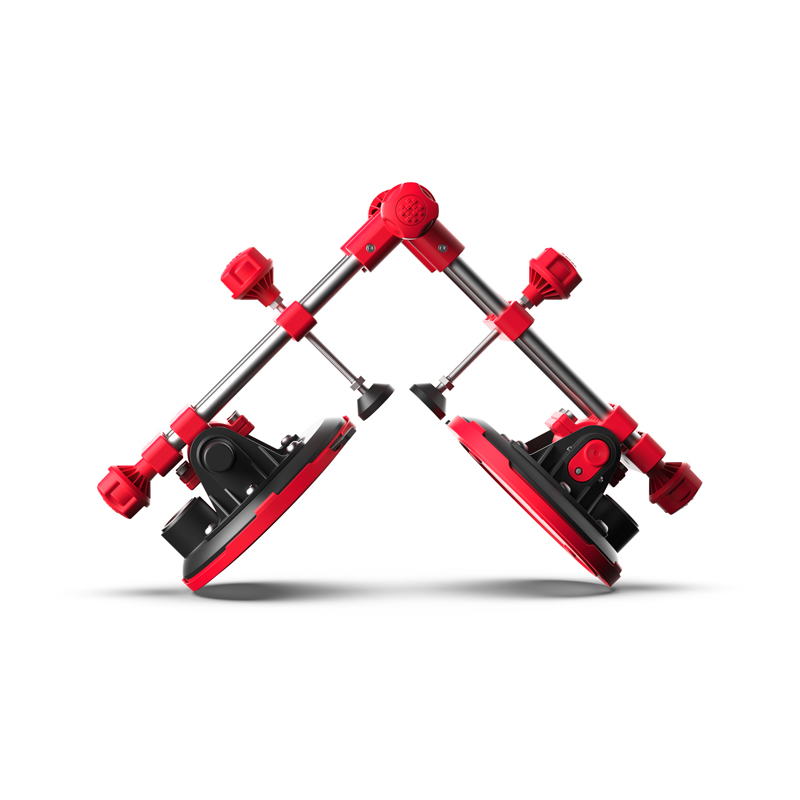

Imagine a sturdy, lightweight aluminum frame, easily assembled and positioned directly beneath the target tile grid. The Tile Lifting Frame acts as a stable, elevated platform and a precision lifting mechanism. Its key innovation lies in the integrated lifting arms or vacuum systems designed to securely grip the tile. Shijing Tools offers robust solutions featuring reliable vacuum lifters integrated within their Tile Lifting Frame systems. These powerful suction cups attach firmly to the tile surface, distributing lifting force evenly and eliminating the point stresses that cause cracks during manual handling.

The operation is straightforward yet transformative:

Position the Tile Lifting Frame beneath the target tile.

Extend the lifting mechanism (vacuum lifter arms) to gently contact the tile.

Engage the vacuum, creating a secure bond.

Use the smooth, controlled lifting action of the Tile Lifting Frame to lower the tile safely down to the working level.

Reinstallation follows the reverse process: position the tile on the lifter, raise it precisely into the grid, and release the vacuum. The Tile Lifting Frame provides unmatched control throughout.

The benefits ripple across the entire renovation process:

Unmatched Tile Protection: This is the paramount advantage. By eliminating manual grabbing, bending, and uneven pressure, the Tile Lifting Frame drastically reduces tile breakage. The secure vacuum grip and controlled vertical movement prevent the chips, cracks, and corner damage common with traditional methods. This translates directly into significant material cost savings – replacing broken specialty tiles can be exorbitant.

Enhanced Worker Safety: Removing the need for workers to stretch precariously from ladders or scaffolding to support heavy tiles overhead dramatically reduces the risk of falls, muscle strains, and repetitive stress injuries. The Tile Lifting Frame keeps workers safely grounded, handling the weight and the height. Shijing Tools emphasizes this safety-first approach inherent in their equipment design.

Dramatic Efficiency Gains: Speed is a major factor in project profitability. A well-designed Tile Lifting Frame allows a single worker to safely remove or install tiles much faster than a two-person team using ladders. Setup is quick, the lifting/lowering action is efficient, and the secure hold minimizes fumbling. Projects progress faster, labor costs are optimized.

Improved Precision & Access: The Tile Lifting Frame allows for meticulous positioning. Tiles can be lowered or raised vertically without tilting, making it easier to navigate obstructions like pipes, ducts, or lighting fixtures within the plenum space. This precision is crucial for complex layouts or when working around sensitive equipment.

Reduced Physical Strain: The Tile Lifting Frame shoulders the literal heavy lifting. Workers avoid the fatigue and potential long-term injury associated with constantly supporting weight overhead in awkward positions. This s to a more productive and sustainable workforce, especially on large-scale projects involving hundreds of tiles.

Shijing Tools understands the diverse needs of the market. Their approach to the Tile Lifting Frame often includes considerations for portability (lightweight aluminum frames), ease of assembly, and compatibility with different tile sizes and weights through adjustable components and appropriately sized vacuum lifters. Durability is key, as these tools face daily use on job sites.

Consider a large commercial office retrofit. Using traditional methods, replacing a ceiling tile might require two workers: one on a ladder carefully removing the tile while supporting its weight, passing it down, then reversing the process for the new tile. With a Tile Lifting Frame, a single worker positions the unit, lowers the old tile smoothly, places the new tile onto the lifter, and raises it precisely into place – faster, safer, and with near-zero risk of damaging the expensive new tile.

While the Tile Lifting Frame represents an initial investment, the return is compelling and multifaceted. Savings accrue from reduced labor time, minimized tile replacement costs, lower insurance premiums linked to improved safety records, and the prevention of costly project delays caused by accidents or material damage. It shifts ceiling tile handling from a high-risk, low-efficiency task to a controlled, predictable, and safe operation.

The adoption of the Tile Lifting Frame signifies a move towards smarter, safer, and more efficient building maintenance and renovation practices. It’s a tool that addresses fundamental challenges head-on, protecting both valuable materials and the workforce. For professionals demanding reliability and performance in ceiling work, integrating a robust Tile Lifting Frame system, such as those engineered for practicality by innovators like Shijing Tools, is no longer a luxury—it’s a fundamental component of a modern, responsible, and productive toolkit. The revolution overhead is quiet, but its impact on safety, cost, and efficiency is profoundly loud.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

.jpg)

-2.jpg)

.jpg)

.jpg)

-1.jpg)

-5.jpg)

.jpg)