You can learn the recent information of Shijing.

A Heavy Duty Vacuum Suction Cup is a versatile tool widely used for lifting, holding, and moving smooth, non-porous materials such as glass, metal, or polished stone. For construction workers, glass installers, or anyone handling large panels, understanding how these suction cups work and how to use them correctly is essential for safety and efficiency. This article will address three common questions: how to properly attach a Heavy Duty Vacuum Suction Cup to glass, how the device functions, and how to test its holding power.

How Do I Properly Attach a Heavy Duty Vacuum Suction Cup to Glass?

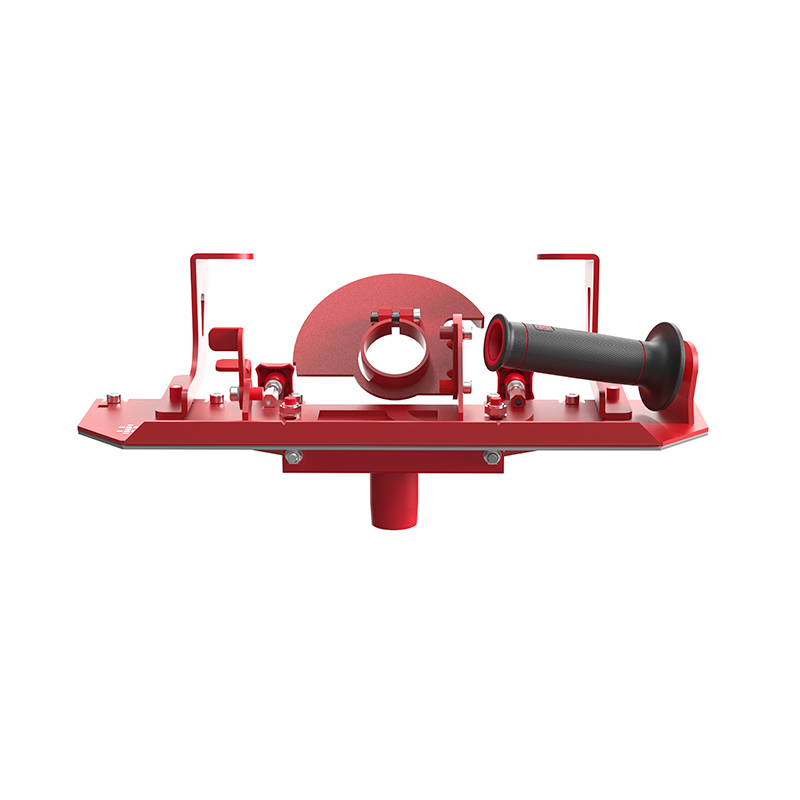

Attaching a Heavy Duty Vacuum Suction Cup to glass is a straightforward process, but it must be done carefully to ensure a secure hold. Here are the steps:

Clean the Surface – The glass surface must be free from dust, grease, or moisture. Even small particles can reduce the suction power of the cup. Use a lint-free cloth and a mild cleaner before attaching.

Inspect the Suction Cup – Make sure the Heavy Duty Vacuum Suction Cup itself is clean and free of cracks or wear. The rubber pad should be flexible and smooth.

Position the Cup – Place the suction cup on the desired area of the glass, making sure it lies flat against the surface.

Activate the Vacuum – Depending on the model, either press down firmly and engage the lever, or pump the handle until the cup seals tightly. This action removes air between the cup and the glass, creating a vacuum.

Check the Seal – Ensure the Heavy Duty Vacuum Suction Cup feels solid and does not shift when you apply light pressure.

When done correctly, the cup will stay securely attached, making it easier to lift or move heavy glass panels safely.

How Do Heavy Duty Vacuum Suction Cups Work?

The working principle of a Heavy Duty Vacuum Suction Cup is based on vacuum pressure. By removing air from beneath the rubber pad, the cup creates a pressure difference between the inside of the cup and the surrounding atmosphere. This difference presses the suction cup firmly against the glass.

Key components that make this possible include:

Rubber Pad – Creates a tight seal on smooth surfaces.

Pump or Lever System – Removes air beneath the cup to generate suction.

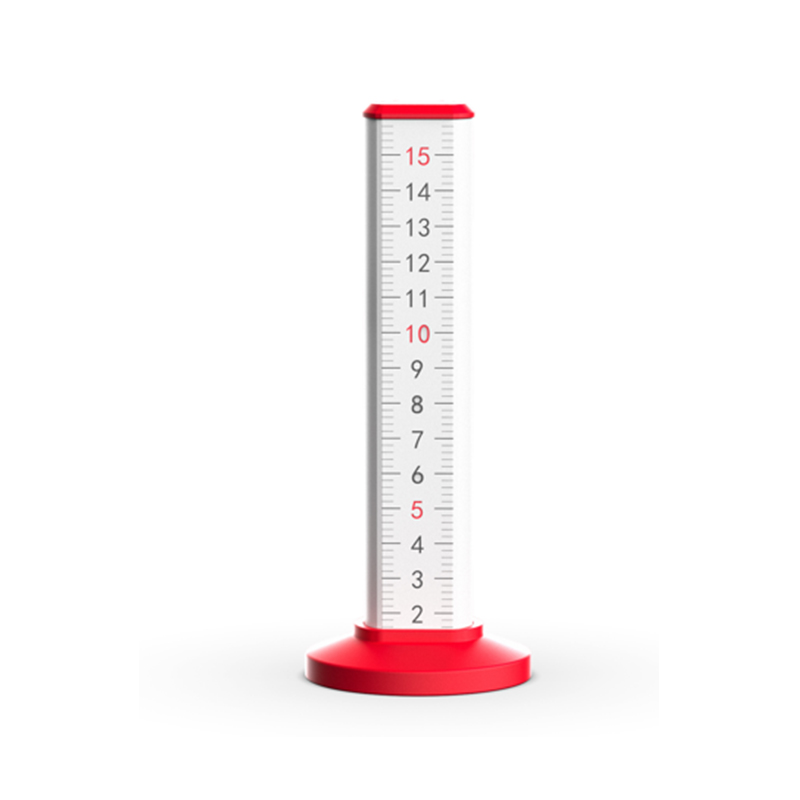

Pressure Indicator (on some models) – Shows whether the vacuum is holding properly.

Because of this simple yet effective design, a Heavy Duty Vacuum Suction Cup can hold considerable weight as long as the surface remains smooth and airtight.

How Can I Test the Holding Power of a Heavy Duty Vacuum Suction Cup?

Testing the strength of a Heavy Duty Vacuum Suction Cup is an important step before lifting heavy glass or panels. Here are some recommended methods:

Visual Check—Look for any signs of air leakage. Some models have an indicator that shows when the vacuum pressure is dropping.

Gentle Pull Test – After attaching, pull lightly on the handle to confirm the cup is firmly secured. If it shifts, reseat and reapply.

Weight Simulation—Before attempting to lift a large panel, test the cup on a smaller, manageable piece of glass. This helps verify that the Heavy Duty Vacuum Suction Cup can maintain suction under load.

Monitor During Use—For long lifts or prolonged holding, check the suction periodically to ensure it remains tight. Some models may require occasional re-pumping to maintain vacuum pressure.

By testing the suction before use, workers can minimize risks and increase confidence when handling heavy or fragile materials.

A Heavy Duty Vacuum Suction Cup is a practical and reliable tool for safely handling glass and other smooth materials. To use it effectively, the surface and suction cup must be clean, the vacuum must be properly activated, and the seal should always be checked. Understanding how these suction cups work helps users appreciate the importance of proper technique, while testing the holding power ensures safety before lifting heavy loads. When applied correctly, a Heavy Duty Vacuum Suction Cup can make demanding tasks easier, safer, and more efficient.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

.jpg)

-2.jpg)

.jpg)

.jpg)

-3.jpg)

.jpg)