You can learn the recent information of Shijing.

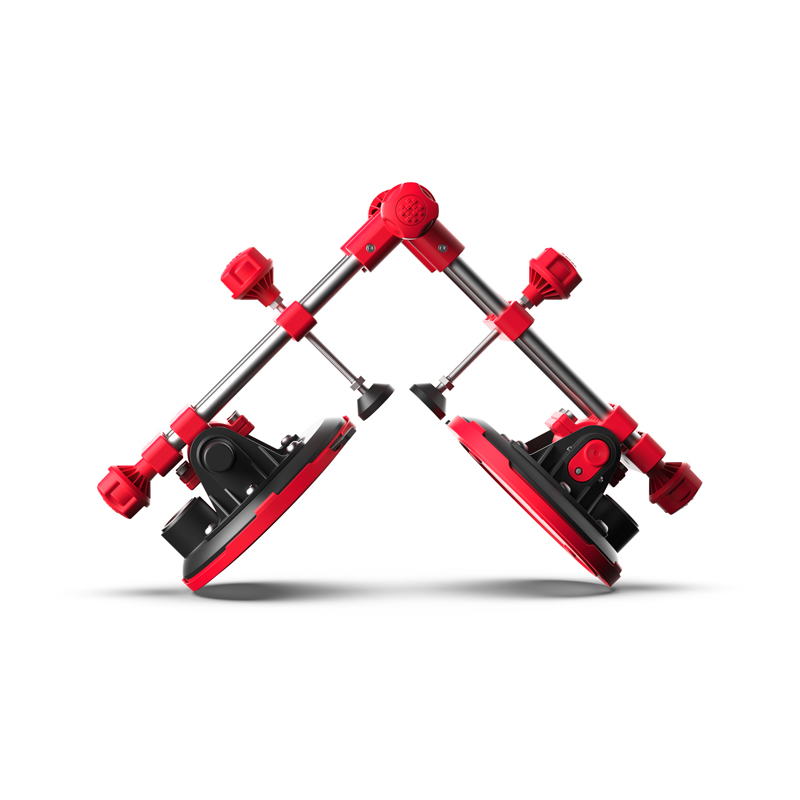

OEM Heavy Duty Vacuum Glass Lifting Suction Cups For Sale

In the world of material handling and automation, Heavy Duty Vacuum Suction Cups play a pivotal role in ensuring precision and safety in lifting, holding, and moving heavy objects. These industrial-grade tools are used in a variety of sectors, including automotive, packaging, logistics, and manufacturing. As integral parts of vacuum systems, they offer gripping power, ensuring that loads are secured reliably during transportation or assembly. However, like all mechanical tools, these suction cups require proper maintenance and care to remain effective and operational over time.

This article delves into the significance of routine inspection and maintenance for Heavy Duty Vacuum Suction Cups. We will explore common problems, such as air leaks, wear and tear, and contamination, providing useful solutions to prevent these issues from disrupting operations. By following these guidelines, businesses can ensure the long-lasting performance of their Heavy Duty Vacuum Suction Cups, reducing downtime and improving overall productivity.

Understanding Heavy Duty Vacuum Suction Cups

Before diving into maintenance practices, it is important to understand what makes Heavy Duty Vacuum Suction Cups unique. These suction cups are designed to handle substantial loads, thanks to their robust construction and powerful vacuum capabilities. They are typically made of durable materials like rubber, silicone, or polyurethane, which offer both flexibility and resilience under pressure.

The suction cup creates a vacuum between the cup and the object it grips, ensuring a firm and secure hold. The size and shape of these cups can vary depending on the application, and their design is crucial in determining how effectively they function.

While they are built to withstand tough working conditions, it’s essential to keep these tools in condition through regular inspection and care.

Why Regular Maintenance is Crucial?

Just as with any piece of industrial equipment, neglecting the maintenance of Heavy Duty Vacuum Suction Cups can to serious performance issues. Regular inspections and timely maintenance are essential for preventing breakdowns that could impact production. There are several reasons why it is important to maintain these suction cups:

Prevention of Air Leaks: A minor air leak in the system can cause a significant loss of suction, affecting the cup’s ability to hold and move objects securely. Even small leaks can result in serious accidents or product damage.

Avoidance of Wear and Tear: Over time, the materials that make up the suction cup can degrade due to repeated use, friction, and environmental factors. Without proper care, this wear can cause the suction cup to lose its grip, to inefficiency and potential safety risks.

Minimization of Contamination: Foreign particles such as dust, dirt, or oil can contaminate the suction cup surface, which compromises its vacuum seal. This can reduce its effectiveness and shorten its lifespan.

Enhanced Longevity: Routine maintenance ensures that the suction cup remains in top condition, its service life and reducing the need for costly replacements.

Common Problems and Solutions

When maintaining Heavy Duty Vacuum Suction Cups, operators should keep an eye out for a few common problems. Each of these issues can be addressed with relatively simple solutions.

1. Air Leaks

Air leaks are one of the frequent problems faced by users of Heavy Duty Vacuum Suction Cups. Even a small hole or crack in the suction cup or its connections can to a significant reduction in its holding power. Air leaks may occur due to wear, improper installation, or damage from heavy lifting tasks.

Solution: Inspect the suction cup regularly for signs of damage, such as cracks or punctures. If a leak is detected, replace the faulty part immediately. Ensure that all seals and connections are tight and in good condition to avoid air leakage. A good practice is to use a leak detector to pinpoint the location of leaks, ensuring that all components are functioning ly.

2. Wear and Tear

Over time, even the durable Heavy Duty Vacuum Suction Cups can suffer from wear. The material of the cup can degrade, becoming brittle or torn, especially when exposed to temperatures, chemicals, or physical stress. This wear affects the suction cup’s ability to form a strong vacuum, compromising its lifting ability.

Solution: Periodically check the surface of the suction cup for signs of wear, including cracks, tears, or thinning areas. When wear is evident, it’s crucial to replace the suction cup to maintain performance. In some cases, applying protective coatings to the cup or selecting cups made of more durable materials can help prolong their life.

3. Contamination

Contamination is another major issue that can affect the effectiveness of Heavy Duty Vacuum Suction Cups. Dirt, grease, or other debris can accumulate on the surface of the cup, preventing a strong vacuum from forming. This is especially problematic in dusty environments or when handling oily or wet products.

Solution: Regularly clean the suction cup using appropriate cleaning agents, ensuring that no dirt or residue is left behind. Avoid harsh chemicals that could damage the material. Implementing a regular cleaning schedule, especially in environments where contamination is more likely, will help maintain the suction cup’s efficiency.

4. Improper Installation

Improper installation of a Heavy Duty Vacuum Suction Cup can cause a variety of issues, from poor grip to complete failure. This can occur if the cup is not positioned correctly, if it is used for a weight it wasn’t designed for, or if the vacuum pressure is not properly set.

Solution: Always follow the manufacturer’s guidelines when installing the suction cup. Make sure it is mounted securely and positioned correctly on the surface. Regularly check that the vacuum pressure is within the recommended range for performance.

Preventive Maintenance Practices

To ensure the continuous and effective operation of Heavy Duty Vacuum Suction Cups, businesses should follow these preventive maintenance practices:

Regular Inspections: Conduct thorough visual and functional inspections at least once a month, depending on usage frequency. Check for signs of wear, cracks, and leaks.

Cleaning and Lubrication: Clean the suction cups regularly to remove contaminants. Use only recommended cleaning products to prevent damage. Lubricate moving parts as necessary to reduce friction and wear.

Check Vacuum Pressure: Ensure that the vacuum pressure is set correctly according to the manufacturer’s instructions. Regularly monitor and adjust it to maintain an effective seal.

Replace Worn Parts: If any part of the suction system appears worn or damaged, replace it immediately to prevent further deterioration.

Train Operators: Train personnel to identify early signs of wear, leaks, or contamination. Proper training ensures that operators can address minor issues before they escalate.

Maintaining Heavy Duty Vacuum Suction Cups is critical to ensuring that they continue to operate at peak performance and remain reliable in high-demand environments. Through regular inspections, cleaning, and addressing common issues such as air leaks, wear, and contamination, businesses can extend the lifespan of their suction cups and improve productivity. By investing in proper maintenance practices, you ensure that your Heavy Duty Vacuum Suction Cups remain effective and safe for years to come, providing secure, efficient, and reliable lifting power every time they are needed.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

-2.jpg)

.jpg)

.jpg)

-1.jpg)

.jpg)

.jpg)